Compact design with high energy

The new CW 3000W by JPT is to drive performance upgrades for laser welding and cutting

Guided by the pursuit of a smaller form factor, JPT, a leading supplier of fiber lasers, has conceived a brand-new design and introduced a new generation of high-power 3 kW continuous-wave fiber lasers. Compared to the previous single-module laser design, this new generation laser achieves a 56 percent reduction in volume and a 50 percent weight reduction.

Based on the standard model, the laser source of the new CW 3000W has multiple upgrades as given in the table. The new version of the laser adopts network communication, which has a long transmission distance and strong anti-interference ability, making it more convenient for system integration. At the same time, the key switch has been given a more concise appearance and a QBH spring protection ring protects the laser output head.

There are many performance advantages for the new CW 3000W, the first of which is power linearity: with the help of multistage power correction, the laser power output is more linear. The offset is less than three percent; the product consistency is higher, which is more obvious in high-end applications.

Second is the response time for the laser to emit a signal. The analog signal response time of the standard machine is over 500 μs, and the analog quantity response time of the new version is less than 50 μs. The response time of PWM and enable is less than 10 µs, which provides higher adaptability in special application scenarios such as high speeds and high frequencies.

Third, power compensation is worth mentioning: the new version of the laser has a 10 – 15 % power buffer. The software sets the expected power value internally. When an irreversible power decay occurs, it can automatically adjust the laser current in real time to maintain the long-term stable and efficient energy output of the laser. It is possible to set a power PD to monitor the laser intensity: When the power decays and cannot reach the setting value, the current will be increased so that the laser intensity reaches the desired value.

Fourth, power can feedback in real time in the following two ways:

- Analog output power can be measured by the external analog voltage output (0 – 4 V).

- Network output can read the feedback power directly through the suffix.

Fifth, the new machine can adjust its output power from 1 – 100 %. It can work even when the power setting is less than 10 %. The greater the controllable range of energy, the wider the application range. Here please note that the linearity within 3 % is not guaranteed when the output power is less than 10 %. The real laser output power may have some deviation, compared to the power setting.

|

|

|

New model |

Standard model |

|

Compact design Large energy |

Dimension |

Compact |

|

|

Power buffer |

10 – 15 % |

<10 % (2,000 W) <5 % (3,000 W) |

|

|

Higher performance |

Power linearity |

<3 % |

<3 % (Premium version) N/A (standard version) |

|

Signal delay for analogy output |

<50 μs |

<50 μs (Premium version) ~ms (standard version) |

|

|

Network port function |

Yes |

Yes (Premium version) N/A (standard version) |

|

|

More comprehen- sive functions |

Power compensation |

Yes |

Yes (Premium version) N/A (standard version) |

|

Power feedback |

Yes |

Yes (Premium version) N/A (standard version) |

|

|

Adjustable power range |

1 – 100 % |

10 – 100 % |

|

|

Power increase and decrease slowly |

Yes |

N/A |

|

|

Laser use time |

Yes |

N/A |

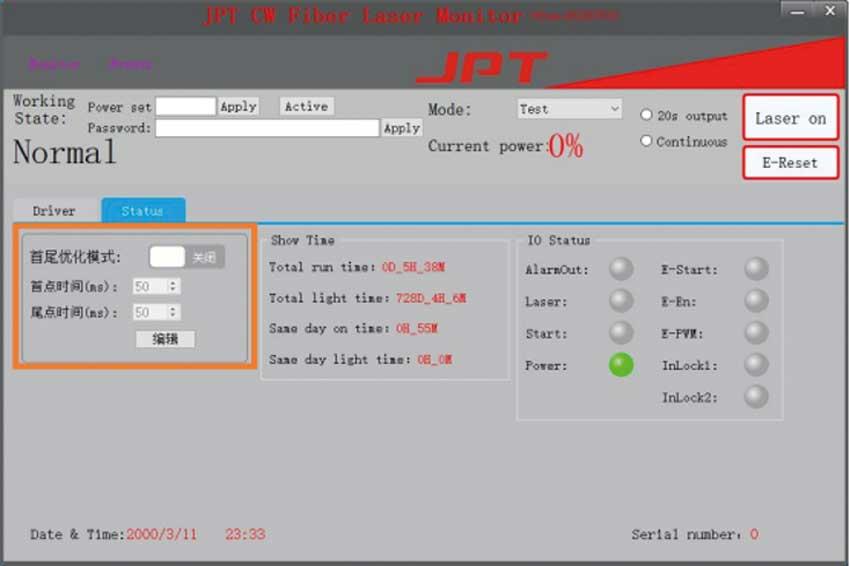

Sixth, there are new functions in the software. Power increase and decrease slowly: the first and last energy can increase or be increased slowly by the monitoring software, which meets more application scenarios. So far, the settable time range is 3 – 500 ms. Laser user time: the laser monitors and displays the actual laser output time so that it can calculate the actual running time.

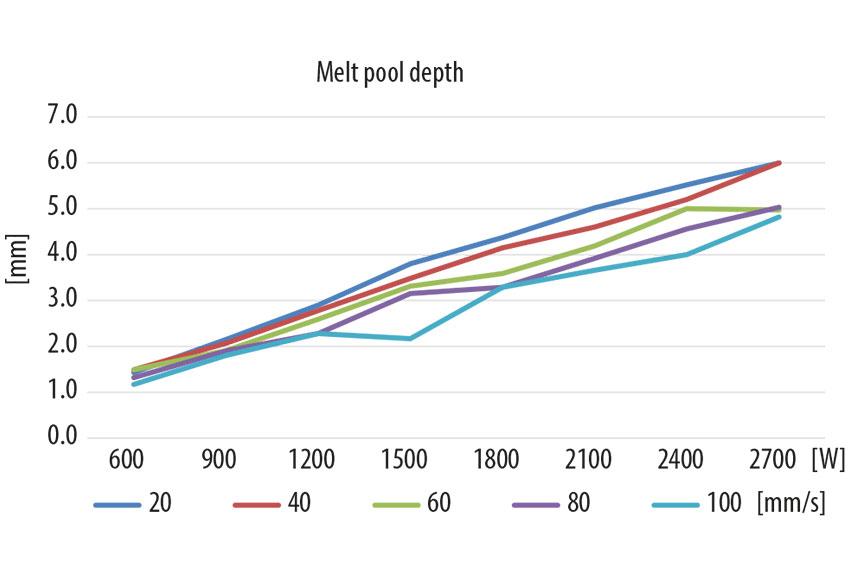

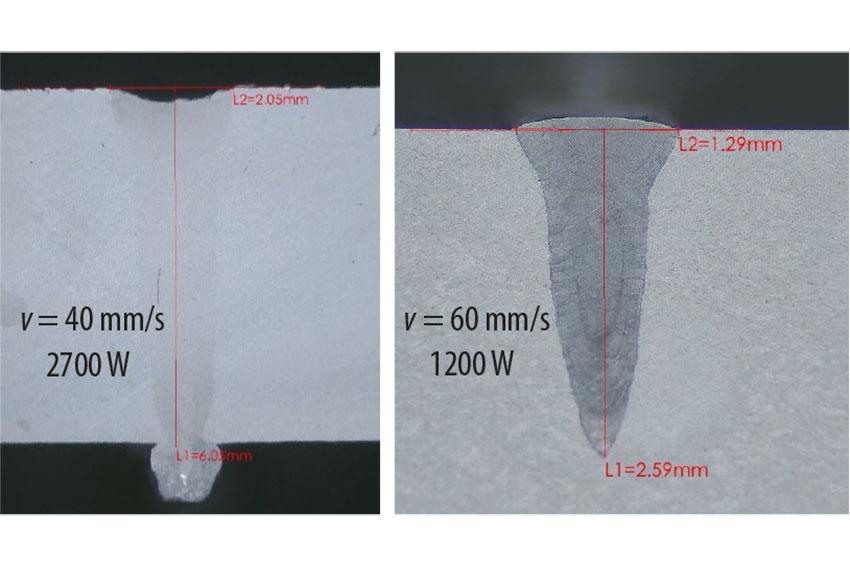

Seventh, welding performance possesses notable characteristics (see Fig. 1):

- When welding a 6 mm piece of aluminum, the depth and the width of the melt pool increase at higher powers. At higher speed, the melt pool depth and width decrease.

- When testing at a low speed and 2.7 kW, the laser can be used to weld through 6 mm aluminum.

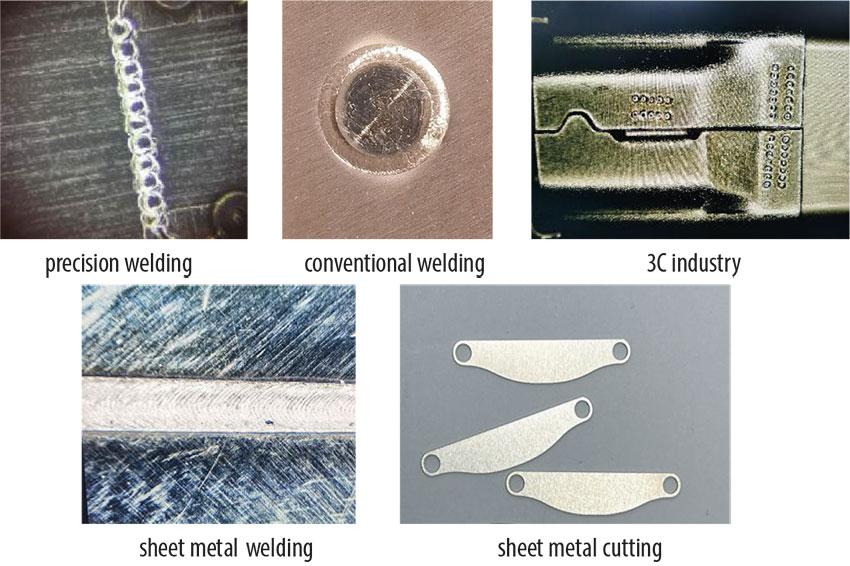

Lastly, there are some advantages for modulated frequency and power stability. In a welding cable test at different frequency from 1 kHz to 20 kHz under low pulse width, the results show that higher frequencies produce a more uniform and denser light spot.

In summary for power stability:

- Under the same parameters, the larger the pulse width is, the larger the size of the point is. Increasing peak power also increases the size of the point.

- In a 6 × 6 array point testing, it has stable and focused energy, uniform welding point, stable light output, all of which can meet the needs of precision welding.

The new CW 3000W has a much smaller volume, making the entire machine smaller. Based on this, the power linearity is also improved; the machine retains a power buffer of 10 – 15 % to ensure its service life. The new version of the laser also has an improved response speed of analog signals and has a large degree of compression for light output delay. In high configuration models, new functions are available in the software control, making control operations more intelligent and more adaptable to different application scenarios. It is suitable for cutting, welding and other application scenarios to meet the application needs of different customers.

JPT’s new CW 3000W has greatly improved the efficiency of going from raw materials to finished products, as well as significantly enhancing the user experience. It meets the users’ demands for convenience, cost-effective transportation, and space-saving installation.

Contact

Shenzhen JPT Opto-electronics Co., Ltd.

1-12F, Building A, Kemron Science and Technology Park, Guanlan Hi-tech Industrial Area, Guanlan Town, Longhua

Shenzhen, 518110

China

+86 755 29528-181

+86 755 29528-185