A Smart Solution to Complex Code-Reading Situations

08.10.2020 -

While barcodes are becoming smaller and packed with more information, they are increasingly used in complex applications. Therefore, intelligent barcode readers need to master various challenges in the industrial fields.

In 2019, vision solutions provider Hikrobot released the new smart code reader ID series. After successfully introducing the first ID series product, the ID6000, to the market, the company went on to launch the ID3000 and ID5000 successively. Today, the ID series products have been proven to be optimal choices for those who are seeking for reliable code-reading solutions in demanding tasks.

Barcode Trends

Barcode is a carrier of information. It can contain the country of production, manufacturer, commodity name, book classification number, origin and destination of express, category, production date, etc. Consequently, barcodes are widely used in commodity circulation, library management, postal management, banking system and many other fields. Generally speaking, assigning a barcode that contains related information to every single product is a universal method to realize the track & trace and quality management in modern manufacturing industry.

It is a trend that barcodes are becoming smaller in size while richer in information storage, which requires higher processing capability of barcode readers. Besides, in certain industries, barcodes are directly marked onto objects, such as metal parts in automobile industry or PCBs in consumer electronics industry. In those occasions, a more robust code-reading performance is desired to avoid the influence generated by the reflection on the surface or the distortion due to irregular object shape.

Barcode Reading Applications

ID series smart code readers are designed to meet diversified demands from diverse industry fields. Embedded with deep learning hard cores and self-developed high-performance algorithms, the ID series can easily deal with the barcodes in complex situations such as film coverage, poor printing quality, reflective surfaces, low-contrast backgrounds, etc. Particularly, the ID3000 and ID5000 series feature modularized field-interchangeable optics and lightings which are favored by industrial code-reading applications in mixed-model manufacturing lines.

Logistics

In the logistics industry, it is necessary to record the information of each parcel in the process of inbound, outbound, sorting, distribution and so on. If these tasks were to be carried out by humans, it would be not only be a waste of time, manpower and financial resources, but they would also generate a large number of errors. The ID6000 series smart code readers are specifically designed for logistics scenarios. Unlike handheld barcode scanners which still require manpower to handle parcels, the ID6000 smart code readers can be mounted directly above or aside the conveyor belt and automatically scan parcels when they pass by. Featuring ultra large resolution (up to 5440*3648), the ID6000 is able to provide a large field of view and reduce deployment cost while maintaining a stable and robust code-reading performance.

PCB Manufacturing

PCB manufacturing is the key process in the consumer electronics industry. In the PCB manufacturing industry, 2D codes are used to record production time, location, soldering temperature, flux density, batch number, test information, etc. As the information extent keeps increasing and the code sizes are shrinking, the requirements on code reading systems tend to become more rigorous. The ID series smart code reader is able to steadily locate and recognize tiny 2D codes with high accuracy thanks to its powerful deep-learning algorithms. Moreover, the optional integrated red light-source (ID3000/ID5000 provide an integrated light source) can effectively increase the contrast for PCB inspection.

Automotive

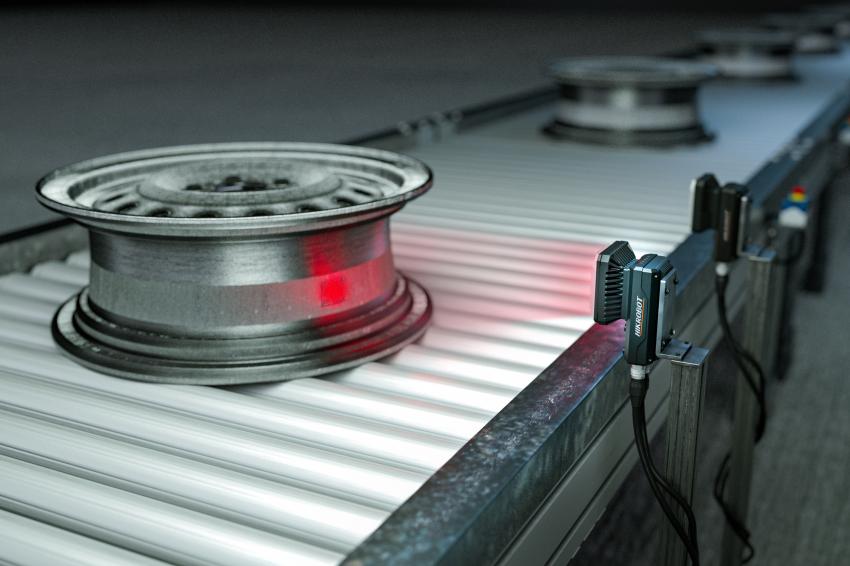

The modern automobile industry is paying more and more attention to the quality and safety of cars. The complete and accurate recording of the serial number, production batch, production date, and other information of various parts in the production and assembly is the key to guarantee both product quality and safety. Data matrix codes are often printed directly, by laser, onto key components such as engine blocks, connecting rods and clutches to realize traceability. However, the code contrast is usually poor, and the component surfaces are sometimes covered by oil. With the help of deep learning code-reading algorithms, the ID3000 and ID5000 can easily deal with stain, defect, low contrast, and other interference. At the same time, the 4-way independently controllable lights provide a more flexible approach to restrain the reflection on metal.

Food & Packaging

In the food and packaging industry, the demand for decoding efficiency and recognition rates is still valid, but the core concern is different to some extent. Since the inspected object is on a relatively fixed position on the conveyor and the movement is very fast, people usually focus more on the processing speed and care less about the field of view or depth of focus. The ID3000 and ID5000, in this case, are the ideal options by virtue of their high frame rate and flexible modular design, which are a natural fit for mixed-model manufacturing lines. On top of that, ID5000 also supports mechanical auto-focus to further ease the setup and maintenance.

Requirements vary in different application scenarios. To choose an appropriate smart code reader based on real needs is the key to succeed in mastering modern code-reading challenges. The Hikrobot ID series is a reliable product that dares to face any challenge of the task.

Contact

Hikvision Europe

Dirk Storklaan 3

2132 PX Hoofddorp

Netherlands

+31 23 554 2770

+31 23 5631112