Choosing the Best Lighting Configuration for an Application

Comparison of different types of lights

Lighting is a hugely important consideration in machine vision, including the choice of form factor. While every little variation influences the outcome, every shape has an influence on the illumination effect, too.

Not only is sufficient intensity needed to receive images with low noise, but the direction, angle and wavelength of the illumination are also important. These, coupled with the nature of the particular work piece, the target information required, and the rest of the inspection environment determine the best choice for the particular application.

In this article we look at one of these essential lighting criteria: the choice of lighting form factor. There are many lighting configurations to choose from, and even within a particular form factor there are variations which can significantly influence the appearance of the output image. Each shape produces its own illumination effect which works for some applications but not others.

Ring Lights

Ring lights are used to illuminate the complete work piece from above, with the camera looking through the center of the ring. This is the most common technique for illuminating diffuse, non-reflective objects and is used in applications such as OCR, 2D code reading, general visual inspection including for damage or stains, inspecting parts on PCBs, etc. Ring lights can feature LEDs mounted on a flexible circuit board which can be adjusted to different angles in order to concentrate the light on the center of the work piece. This gives multipurpose bright field illumination which alleviates the influence of slight positional or inclination deviations in the work piece for stable imaging.

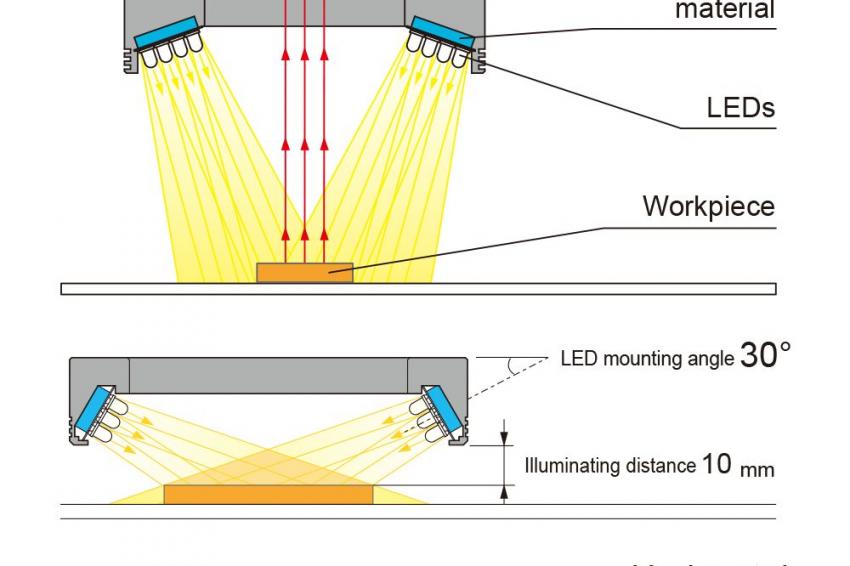

Low Angle Ring Lights

Low angle ring lights are also available. In this case the LEDs are mounted to a flexible circuit board within the ring in a steep angle. This allows the light to be mounted much closer to the work piece, illuminating it at a very low angle to give dark field illumination which highlights surface features since the camera only receives light that has been scattered by a defect on the surface. Typical applications include inspection for engraving, damage, or stains on metal surfaces, edge extraction, inspection for foreign material mixed on medical devices, inspection for damage to glass edges, visual inspection for O-rings, etc. It is also possible to have very thin low angle ring lights where the LEDs are mounted horizontally within the ring. Because they are so thin, these lights can be mounted very closely to the work piece, again giving dark field illumination. However, because the angle of illumination is so low, only the finest surface details are picked out. Figure 1 shows these different ring light geometries. One general characteristic of these types of ring light is that the intensity of illumination tends to be greater at the center of the work piece. For a more even illumination with reduced shadowing diffuse ring lights can be used.

Diffuse Ring Lights

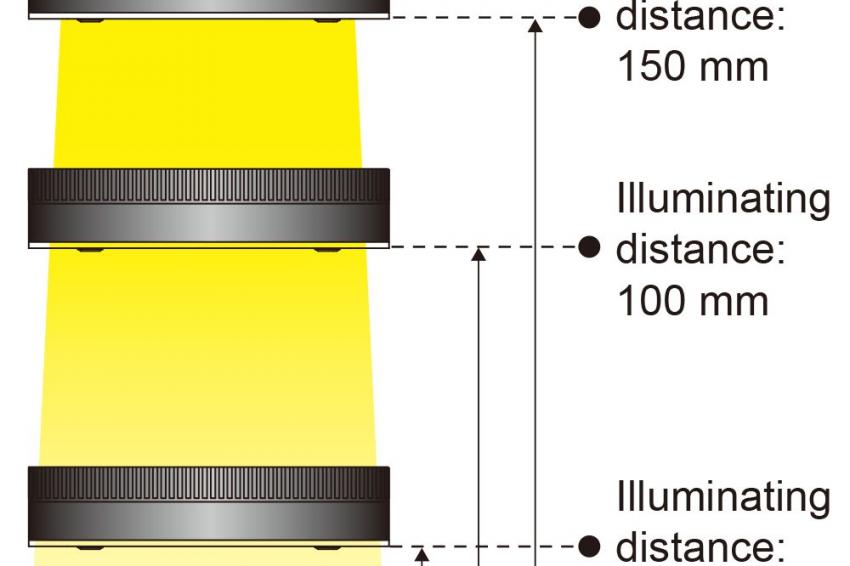

Diffuse ring lights use surface-mounted LEDs with a diffuser plate, and there is little variation in the uniform illumination region even if the distance of the light from the work piece is changed. This means that they can be used for both high angle and low angle illumination. Figure 2 shows diffuse ring light configurations.

Bar Lights

Bar lights are versatile illumination systems which provide oblique lighting. They give flexible bright field/ dark field lighting depending on the number of lights used and the installation position and angle with respect to the workpiece. This flexibility allows the light to be positioned to get the optimal image. LEDs are arranged in straight lines to provide direct illumination and are available with a choice of length and number of rows. By using lenses, it is possible to provide convergent illumination for narrow spaces or diffuse illumination for wide areas.

Dome Lights

Dome lights provide an even and homogeneous illumination of the work piece and can be used to illuminate complex reflective shapes. They can be used for visual, text, or color determination inspections on glossy surfaces, curved surfaces, or uneven surfaces; inspection for engraving, damage, or stains, inspection of metal with hairline features; inspection of parts on circuit boards, etc.

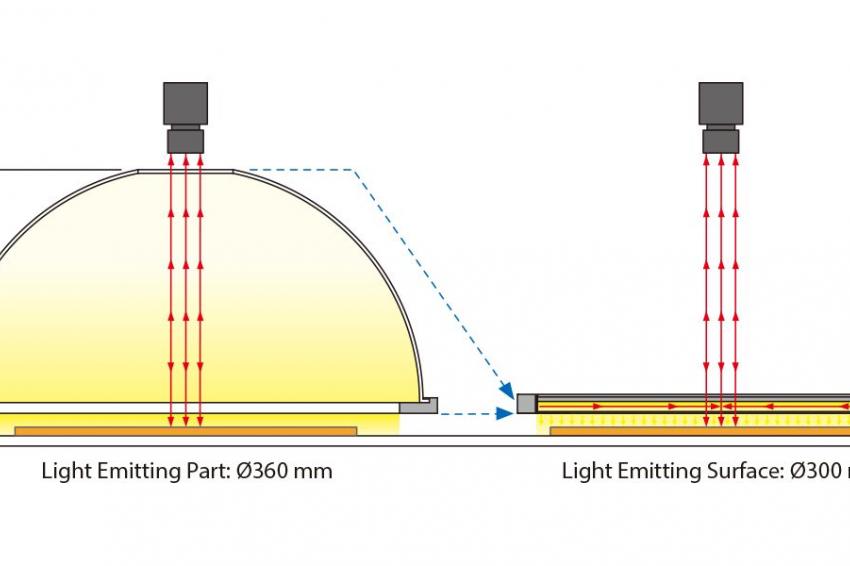

Light from surface-mounted LEDs is diffused by the dome-shaped reflective panel to give uniform illumination, with little change even if the distance to the work piece is changed. This type of lighting can be used in a wide range of industries. An alternative way of producing diffuse, uniform illumination is to use a flat dome. This recreates the effect of dome lights in a thin enclosure. The special light guiding plate used creates a bright clear view with no hole needed for the camera. A fine surface dot pattern on the surface of the plate virtually eliminates image irregularities and Moire effects in the image. Flat dome lights also eliminate the dark spot caused by the camera hole in traditional dome lights.

Since flat dome lights occupy less room than a dome light, they can be used for applications with limited space. Figure 3 compares the geometry of flat dome lights with dome lights. While flat dome lights give illumination equivalent to a dome light when positioned close to the work piece, they also provide coaxial illumination when they are used further away from the work piece.

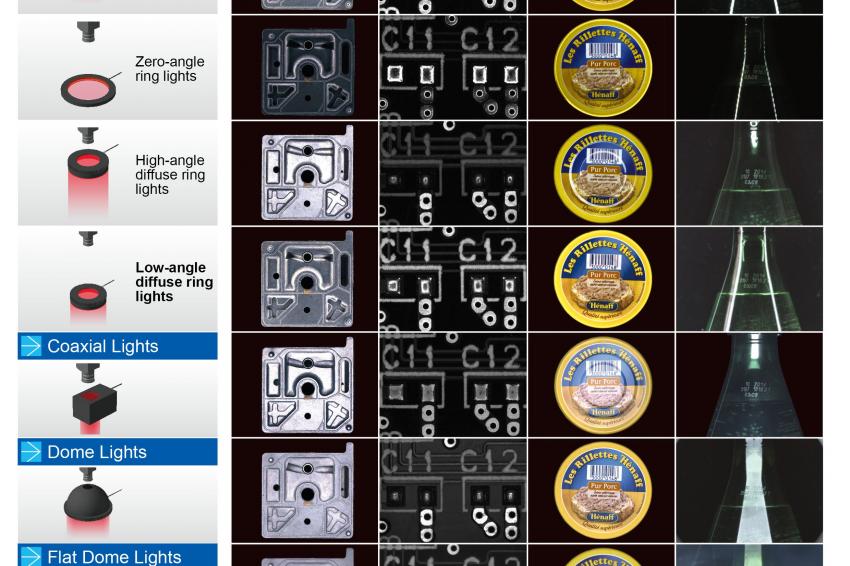

Added Versatility

Figure 4 shows the diversity of illumination effects that can be achieved on different types of work pieces using the various form factors discussed. These were produced using white LEDs, but all of these form factors are available in a variety of sizes and with a choice of LED power and wavelengths adding even greater illumination options. In addition, the lights can be overdriven to produce higher light intensity in short pulses using external lighting controllers, or in some cases, built-in lighting controllers. Of course, these are only a selection of form factors available for machine vision applications. Others will offer different image details, so it is important for users to discuss their requirements with lighting specialists to get the optimum set-up for their application.