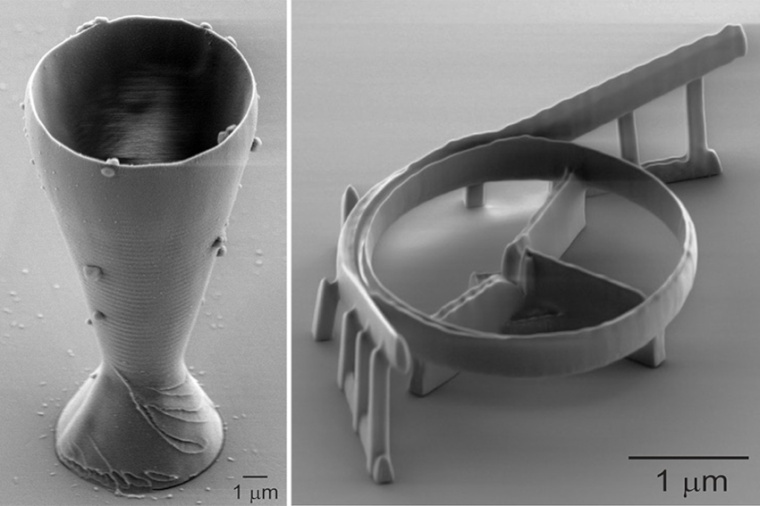

Researcher 3D prints world's smallest wineglass

A new simplified technique for creating silica glass structures.

Researchers have 3D-printed the world’s smallest wine glass nearly indistinguishable with the naked eye. But the idea wasn’t to cater to extremely light drinkers. Rather, the glass was printed to demonstrate a new simplified technique for creating silica glass structures for a range of applications from telecommunications to robotics. Developed at KTH Royal Institute of Technology in Stockholm, the new technique surmounts complications such as the need for thermal treatment when 3D-printing essential silica glass components, says researcher Frank Niklaus.

Niklaus says it can be used for customized lenses for medical machinery that perform minimally invasive surgery, microrobots that navigate extreme environments, or filters and couplers for fiber optic networks, to name a few applications. One such fiber optic filter was produced in the study. The researchers show that the technique can print devices directly on the tip of an optical fiber as thin as a strand of a human hair. “The backbone of the internet is based on optical fibers made of glass. In those systems, all kinds of filters and couplers are needed that can now be 3D printed by our technique,” says Kristinn Gylfason from the devision for micro- and nanosystems at KTH. “This opens many new possibilities.”

The method drastically reduces the energy needed to 3D print silica glass, which normally requires heating materials up to several hundred degrees for hours, says Po-Han Huang, a doctoral student at KTH. “The advantage of our method is there’s no need for thermal treatment and the glass can withstand extreme heat in applications.” Another benefit, he says, is that the method can produce silica glass using readily available, commercial materials.

Eliminating the need for thermal treatment increases the possibility for the technique to be used widely in various application scenarios, he says. “The concerns when integrating 3D printing methods are usually different for different applications. Even though optimization of our method is still required for different applications, we believe our method presents an important and necessary breakthrough for 3D glass printing to be used in practical scenarios.” (Source: KTH)