Programmable laser beams save energy

There is a new quality in laser material processing: With a liquid crystal modulator, the beam profile of a laser can be freely programmed with high temporal resolution, but also split into identical copies. The target is to achieve energy savings of at least 30 percent compared with conventional processes.

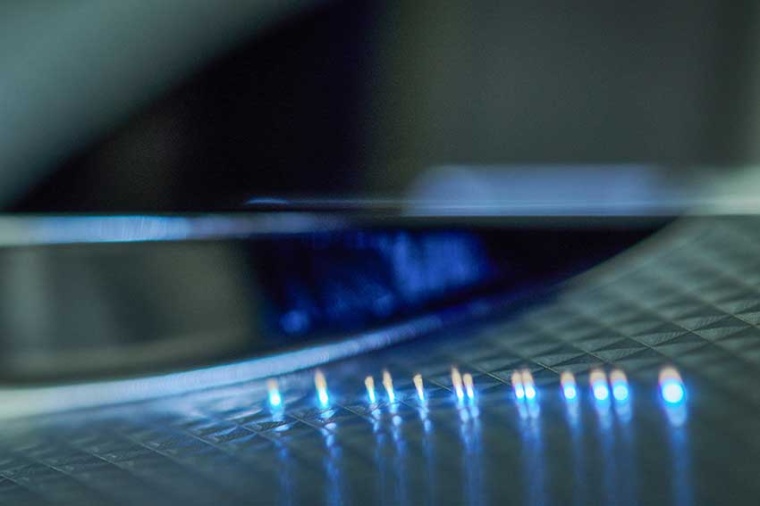

Much has been heard of ultrashort pulse (USP) lasers: With pulses in the pico- or femtosecond range, they can ablate even the hardest materials and do so with micrometer precision. Now that USP lasers are available with several hundred watts of output power. In addition to various USP lasers, the team at Fraunhofer ILT also has the latest high-performance liquid crystal modulators for beam shaping in laser material processing. These modulators can tolerate up to 150 watts of laser power. In the EU project “Metamorpha – Made-to-measure micromachining with laser beams tailored in amplitude and phase”, two of them are connected together in an optics module. This module can shape a beam profile individually or as a multi-beam and is compatible with various machines, for example 3-axis machines, 5-axis machines, turning machines or roll-to-roll.

A major advantage of liquid crystal modulators is their ability to change the beam shape more than 60 times per second, which makes it possible to optimize the machining process or even change the process in a closed control loop. For this purpose, the process is continuously monitored and regulated with an intelligent control system. The process parameters and strategy are optimized using machine learning, which aims to produce parts that are completely free of defects. After a corresponding learning phase, processes can also be simulated and optimum process parameters predefined.

The main aim of the project is to save a significant amount of energy and resources in production. This is of particular interest to the three industrial partners Ceratizit, Thyssenkrupp and Philips. They all have processes for which the planned laser-based manufacturing approach would mean enormous progress towards sustainable, economical production.

At Thyssenkrupp, the laser is to structure embossing rolls. These are currently processed by electrical discharge machining, which consumes more than 10 GWh per year, of which the laser is expected to save 90 percent. Thanks to precise restructuring of worn surfaces with the laser, the lifespan of the embossing rollers should be increased ten-fold. Ceratizit plans to use the laser-based process to manufacture carbide punches and embossing dies and to recondition worn-out tools. A photonic process chain is to make this happen faster and more economically. And Philips wants to greatly simplify product manufacturing for the consumer sector by using a universal laser processing head.

EU project metamorpha

Together, the project partners want to bring together the latest laser technology, process knowledge and control know-how to replace established processes such as spark erosion or wet chemical etching and thus significantly save energy and resources. The reprocessing of tools by means of laser material processing is also an important step towards the sustainable use of resources. The project started on September 1, 2022 and is funded by the European Union for a period of four years.

Company

Fraunhofer Institute for Laser Technology ILTSteinbachstr. 15

52074 Aachen

Germany

most read

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.

Lapp Group takes over JJ-Lapp completely

JJ-Lapp will now become a wholly-owned subsidiary of the Group, with financial details remaining confidential.

Machine Safety 2026: The Five Most Important Trends for Eutomation Engineers

Digitalization and automation continue to drive mechanical engineering forward - and with them, the requirements for functional safety and cyber security are increasing. For automation engineers, this means that machine safety is becoming a holistic concept.

Purdue University, Rittal and Eplan work together

As part of this partnership, Purdue will open two exclusive laboratories.