Precise measurement and analysis of the smallest details

Diverse 2D/3D machine vision in macro- and microscopy

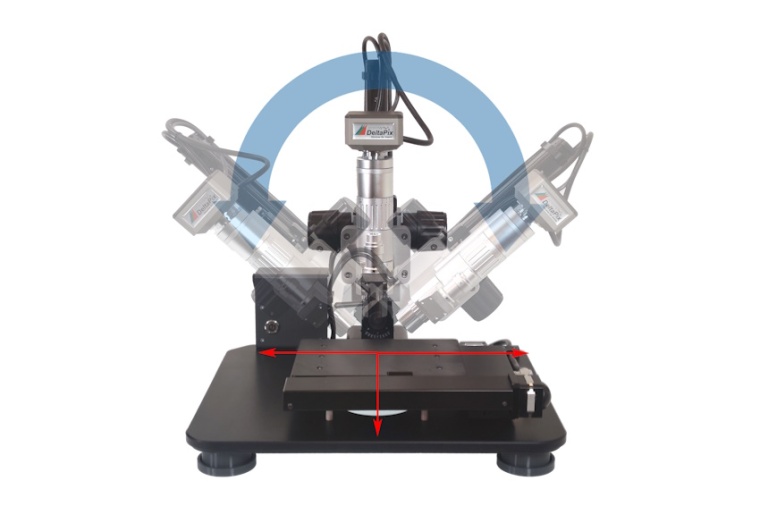

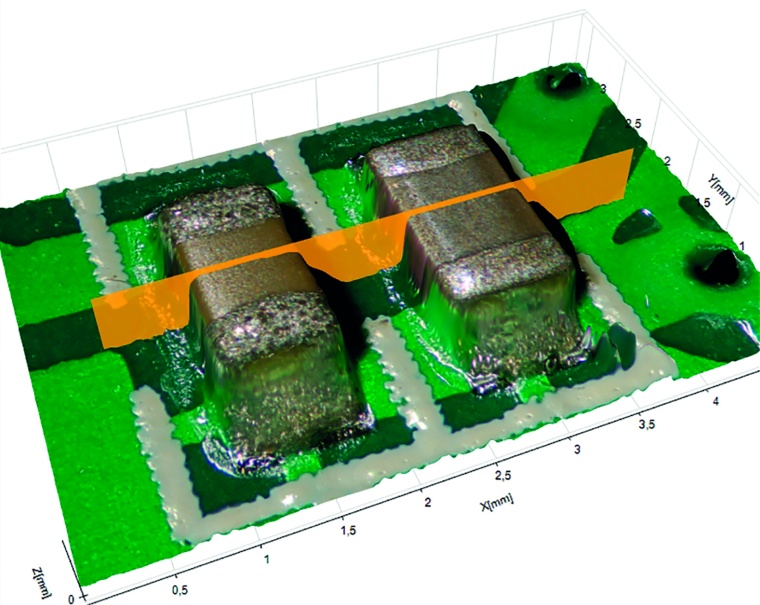

Super depth of field through focus stacking – with up to 250 focus positions combined to a 2D/3D image – provides a very extensive expansion of analysis options compared to classic 2D machine vision.

Deltapix's modular inspection systems and the new Deltapix InSight 7.0 software provide ease of use for a wide range of micro- or macroscopy applications. High image quality increases the speed and precision of inspections, analyses, measurements and detailed visual documentation. These systems are used for example in industrial quality laboratories, but also in medical or biological applications.

This microscope software suite for precise measurement, analysis and control of microscopes, cameras, motorized stages and other connected devices offers a modern, intuitive user interface. It contains a basic package (included free of charge with most Deltapix cameras) and a number of optional additional modules that offer extensive functionality as well as special applications.

The most important modules are:

- Insight Basic Plus: With extended focus and exposure functions and much more.

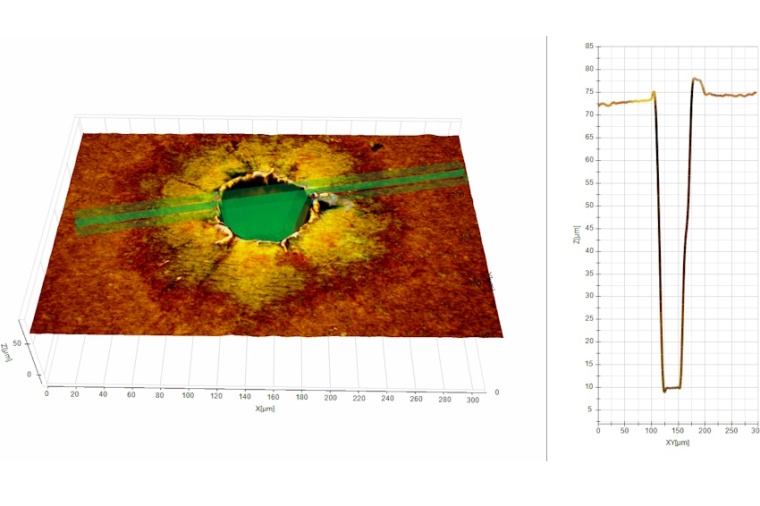

- 3D topography: For detailed surface analysis and 3D measurement of height, depth, angles, distances and 2D profiles.

- 3D stitching: Stitching of many images to seamlessly expand the 3D view.

- Roughness measurement: Accurately quantification of surface texture and irregularities according to the latest ISO standards (ISO 25178-2:2012).

- Video recording: Capture and documentation of processes in real time or in time lapse.

- Segmentation, counting and multi-phase analysis: Advanced metallographic tools and particle segmentation and counting combined with reporting and automated batch handling of multiple samples.

- Automation: Comprehensive control of lighting systems, stages and microscopes.

This software can be used to calibrate multiple cameras and microscopes individually. An individual exposure time and depth of field can be defined for each lens or each magnification. It is possible to design and create customized reports in Excel or PDF format for measurements and analysis.

The software suite is optimized for its own camera series and includes a wide range of cameras for most microscopy applications. The software also supports selected third-party cameras, as well as SWIR and UV cameras.

Measurement spectrum

Measuring tasks can be: lengths, areas, angles, diameters, volumes, depth, height and roughness profiles, etc. The results can be displayed on the captured image and saved. The measurement data can also be exported to Excel, CSV or PDF files.

The accuracy is in the µm range. The fully automatic 3D stitching with motorized XYZ movement enables details of the object sample with a very high image resolution of 16,000 x 16,000 pixels.

Company

jumavis GmbHAlbgaustraße 1c

76337 Waldbronn

Germany

most read

There’s a Large Hippo Resting in the Mud

Virtual Video Safaris for Blind and Visually Impaired People

SPS 2025: Cautious optimism in automation

A picture of the mood of the German economy

Photonics West 2026: Industrial Machine Vision Takes Center Stage

The new Vision Tech Expo showcases the latest trends in AI machine vision, embedded vision, and 3D sensor technology