OCT for automated conventional welding in the automotive industry

Optical coherence tomography provides robotic GMAW with a process and quality monitoring function

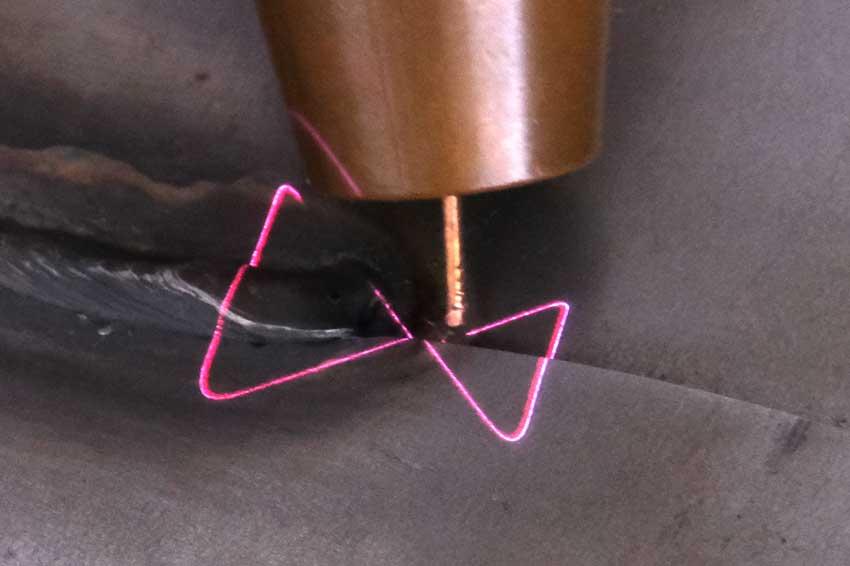

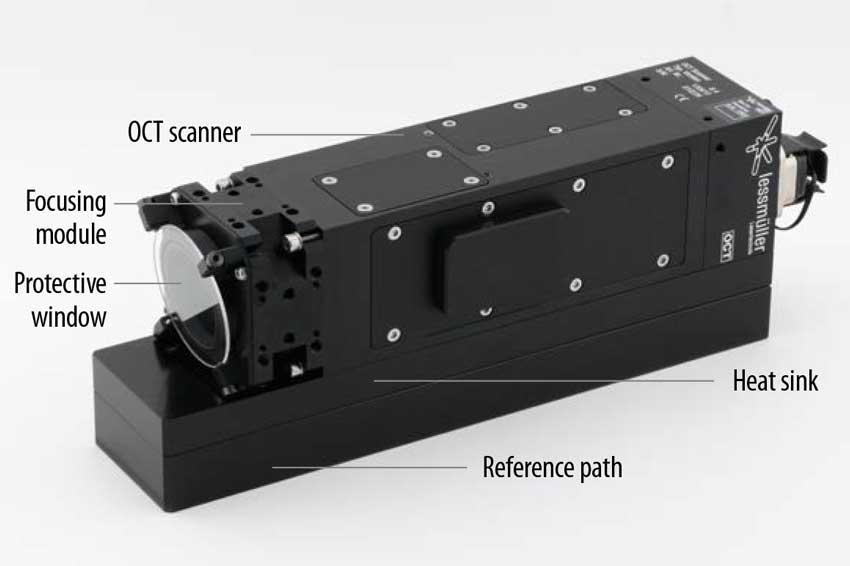

Similar to laser welding, optical coherence tomography (OCT) simplifies the operation of robot-guided, automated GMA welding by offering seam tracking capabilities thanks to its industry-approved, standardized functions and fieldbus communication. Furthermore, OCT can monitor the quality of weld seam online by measuring the seam topography during GMA welding, eliminating the need for time-consuming and costly off-line weld inspection.

Gas metal arc welding (GMAW) is known as the standard welding technique for ferrous and aluminum alloys. It produces high quality, strong, and reliable welds that can withstand various loads and stresses. This makes it a popular choice for applications where strength and durability are critical.

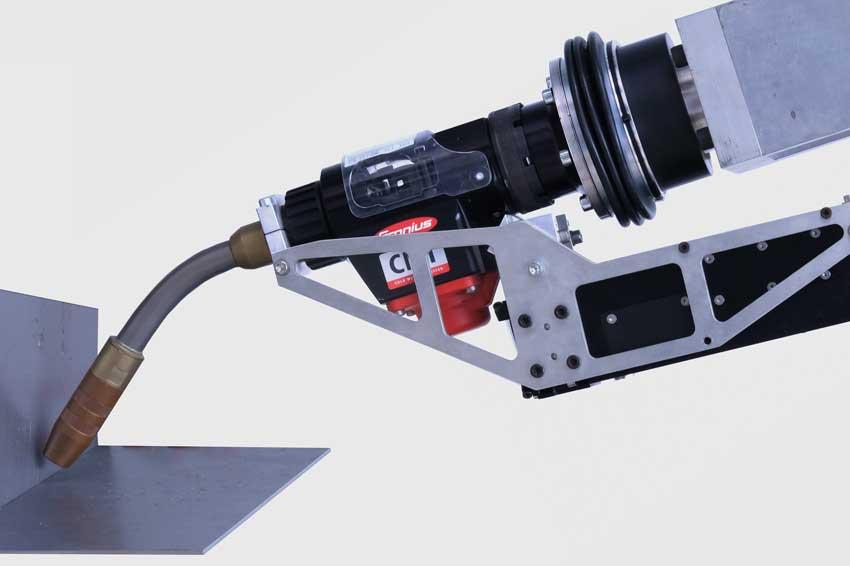

In the past, many large parts were welded by hand. Nowadays, this work is carried out by robots at automotive suppliers that can weld them automatically or semiautomatically on the assembly line. Robot-operated GMAW is boosting the production of electric vehicles. It allows different metals and alloys to be joined at high welding speeds, increasing production efficiency. As wire is always fed to the parts being joined during GMAW, larger gaps can be bridged and the edges need to be prepared less precisely compared to laser welding. It is therefore the first choice for larger parts with wide weld beads.

The welding process must be precisely controlled in order to further improve the productivity of automated GMA welding and reduce the risk of a lack of fusion. Previous process monitoring systems were considered insufficient due to the high performance requirements of robotic GMAW. OCT has recently become widely used for real-time control and process monitoring of laser welding. Coaxially directed onto the workpiece surface together with the processing laser beam, the OCT beam enables topographical surface examination in pre, in, and post-welding process. It provides transparent information about the positioning status of the optics and the workpiece, as well as the weld quality. The advances in OCT technology can be transferred to GMAW, enabling accurate and consistent seam tracking and inspection suitable for the mass production of automotive components.

The experts present their findings at the LaserEMobility Workshop 2024, 16 & 17 July 2024. Read the full article now online or in the September issue of PhotonicsViews.

Reference: N. Deyneka Dupriez & S. Adolph: OCT for automated conventional welding in the automotive industry: Optical coherence tomography provides robotic GMAW with a process and quality monitoring function, PhotonicsViews, version of record online 14 June 2024; DOI: 10.1002/phvs.202400024

Contact

Lessmüller Lasertechnik GmbH

Gollierstr. 12

80339 München

Germany

+49 89 3609048-0