Next-generation night vision technology

A grant from the US Navy will advance sensor technology to improve the effectiveness of night vision and infrared devices made with silicon germanium tin.

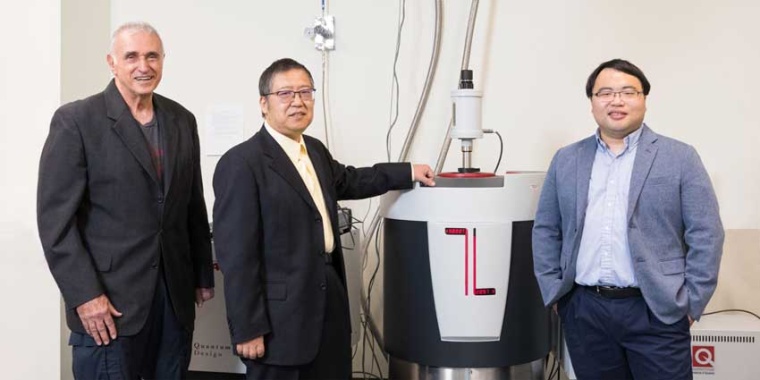

Three U-of-A researchers – electrical engineering professor Shui-Qing “Fisher” Yu, distinguished professor Greg Salamo, and Jin Hu, assistant professor of physics – will collaborate with the Navy Surface Warfare Research Center, Crane Division, and Arktonics, a local company. Together, they will use the semiconductor silicon germanium tin in designing and building the prototype of a superior and less-expensive infrared camera. The military uses infrared imaging technologies for night vision technology.

The grant will pay for specially designed equipment that will help the team develop the infrared imaging sensor array made of silicon germanium tin. The team will then integrate this array with a complementary metal oxide semiconductor – as known from image sensors – on the same chip. The combination is more effective at harnessing ambient light, an essential element in night vision technology.

Current technologies rely on semiconducting alloys such as mercury cadmium telluride and other material-based photodetectors. These alloys have several limitations, including a complex and expensive manufacturing process, low production yield and poor uniformity over large areas. These limitations negatively affect wide-range infrared visibility, especially in areas with poor environmental conditions, such as sandy or hazy environments. These technologies also cannot integrate an infrared camera and other necessary electronics on the same chip, which increases cost and decreases reliability, efficiency and speed.

By more efficiently harnessing light, silicon germanium tin on silicon substrates is potentially a better solution. Yu has worked with silicon germanium tin for more than a decade. In 2016, he and colleagues reported the fabrication of a first-generation, “optically pumped” laser, meaning the material was injected with light, similar to an injection of electrical current. Yu was also the first to report an “electrically excited” germanium tin laser.

Using molecular beam epitaxy, Salamo has been growing semiconductor nanostructures for more than twenty years. He is well known for his work on quantum wells, dots and wires. Meanwhile, Hu has developed and fabricated new quantum materials and investigated their novel quantum properties.

The researchers hosted a Zoom meeting on September 21 to kick off the project. The meeting was attended by US Representative Steve Womack, who helped secure funding for the research.