New kind of open-top optofluidic device

02.06.2021 - Co-planar optoelectrowetting device allows for droplet access from above.

Microfluidic technologies have seen great advances over the past few decades in addressing applications such as biochemical analysis, pharmaceutical development, and point-of-care diagnostics. Miniaturization of biochemical operations performed on lab-on-a-chip microfluidic platforms benefit from reduced sample, reagent, and waste volumes, as well as increased parallelization and automation. This allows for more cost-effective operations along with higher throughput and sensitivity for faster and more efficient sample analysis and detection. Optoelectrowetting (OEW) is a digital optofluidic technology that is based on the principles of light-controlled electrowetting and enables the actuation and manipulation of discrete droplets.

OEW devices have many advantages, such as the ability for large-scale, real-time, and reconfigurable control of picoliter- to microliter-sized droplets by adjusting the number and size of low-intensity optical light patterns incident on the device. With each individual droplet on the OEW device acting as its own bioreaction chamber, the OEW device also has the ability to support multiplex capabilities. This can prove to be beneficial in applications such as single-cell analysis and genomics or combinatorial libraries. Previous traditional OEW devices provide a flexible platform to perform chemical and biological assays such as real-time isothermal polymerase chain reaction with basic droplet manipulation techniques. However, in these OEW devices, droplets are sandwiched between a bottom active OEW substrate and a top layer ground electrode substrate, forcing any input/output fluidic configurations to be integrated from the side openings. Although feasible, this can prove to be limiting for system integration.

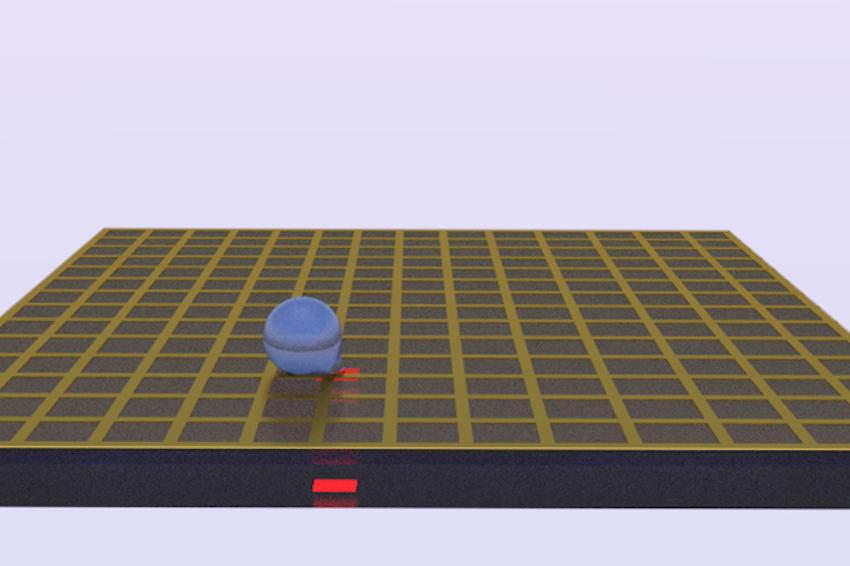

Researchers from the University of California, Berkeley, created a single-sided, co-planar OEW device that allows for individualized and parallel droplet actuation and benefits from easier droplet accessibility from above for more input/output configuration schemes. This was achieved by eliminating the need for a top cover electrode found in traditional OEW devices by fabricating a metal mesh grid integrated on the OEW device. Droplets can still move freely around the two-dimensional device surface and are now accessible from above due to the open-top design. In their research, they have also derived a theoretical model of the co-planar OEW device to better understand how the integrated metal mesh grid affects device and droplet performance. Analysis gathered from the co-planar OEW model was used to optimize the co-planar device structure and operation. They have demonstrated the ability for basic droplet manipulation, such as individual droplet operations in parallel, merging of multiple droplets, and the ability to handle and move droplets with varying volumes simultaneously.

The co-planar device improves on the traditional OEW device's droplet actuation performance with speeds more than two times faster, up to 4.5 cm/s. Higher droplet speeds on the co-planar OEW device achieved despite a marginal reduction in effective force compared to the traditional OEW device can be partly attributed to the reduction in friction due to elimination of the top cover. In addition, the ability to operate co-planar OEW devices with 95% reduced light intensity was demonstrated.

To showcase the benefit of having exposed droplets to accommodate a wider range of input/output configurations, a droplet-on-demand dispensing system from above was integrated with the co-planar OEW device to inject, collect, and position individual droplets and form large-scale droplet arrays of up to 20 by 20, covering the whole device surface area. Creating larger OEW devices should allow for even more droplets to be accommodated on chip. With this research, the team has developed an OEW platform for reliable droplet manipulation that can accomplish most basic biological and chemical benchtop techniques. The co-planar OEW device expands the flexibility and range of possibilities for optofluidic technologies to realize greater system integration capabilities and biological and chemical applications. (Source: SPIE)

Link: Integrated Photonics Laboratory, University of California Berkeley, Berkeley, USA