New clean room for microchip production

DTU is expanding its facilities to meet high demand for microchips from companies and researchers. The expansion will also strengthen the development of quantum computers, which is based on research and development of new chips.

Virtually all electronic products use microchips. For example, a mobile phone contains about 160 different chips, while hybrid electric cars contain up to 3,500 chips. DTU Nanolab conducts research into the micro and nanotechnology on which the production of advanced microchips is based. In addition, DTU Nanolab grants companies and industry access to use the unique facilities in the only large-scale clean room in Denmark. But space is cramped.

The vast majority of all microchips are produced in Asia, including China, South Korea, and Taiwan, while the EU only produces ten percent of all microchips worldwide. But, like China and the United States, the EU now wants to boost its own production of microchips to reduce dependence on producers in the rest of the world.

With a new agreement, the EU will raise € 43 B for microchip production, with € 3.5 B being earmarked for research and development of new chips. The ambition is to increase Europe’s market share to twenty percent before the end of the decade.

“Already today, we’re experiencing great demand for more space. At the same time, we expect demand to increase, as nanofabrication technology is crucial in the development of quantum computers and sensors,” says Jörg Hübner, director of DTU Nanolab.

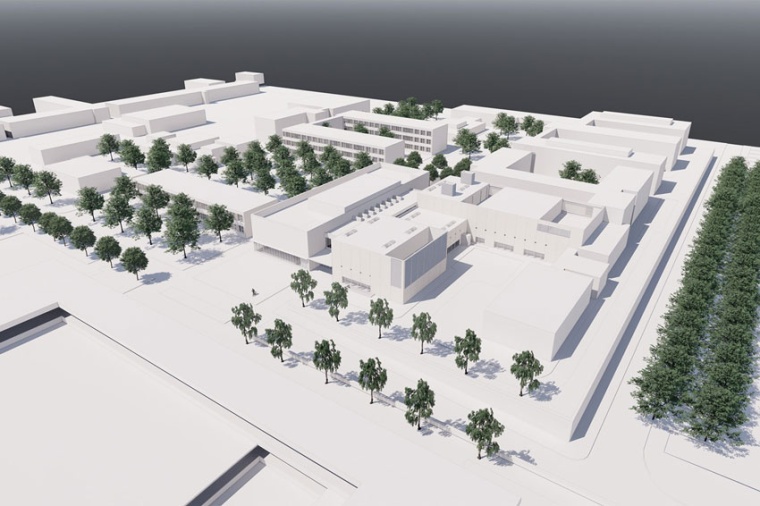

The new cleanroom will be built at DTU Lyngby Campus and comprises an approximately 5,600-m² two-floor building with a basement. The DTU-funded building is budgeted at 345 million Danish krones (approx. 46 million euros) and expected to be completed in 2026.

More space for new technology

“The expansion of DTU's clean room facilities will contribute to strengthening Denmark’s business sector, competitiveness, and digitalization capacity, as well as contribute positively to the European ecosystem for microchips,” says Jörg Hübner.

The clean room was last expanded in 2000 and 2003. DTU currently has 1,350 m² of clean room facilities with a very wide range of machines for production of sensors and microchips. Jörg Hübner explains that – since then – more equipment has been crammed into the clean room, leaving no room for additional equipment, more technologies, large international research projects, or more companies than the over thirty enterprises that currently use the facilities.

“There is a need for more clean room space and equipment if DTU Nanolab is to meet the demand from partners or to launch major research activities,” says Jörg Hübner.

Company

Technical University of DenmarkAnker Engelunds Vej 101

2800 Kongens Lyngby

Denmark

most read

MVTec Innovation Day 2026: Exchange and insights into machine vision

This event, now in its eighth year, offers the machine vision community a platform for networking and professional exchange.

Otto wins IERA Award 2025

Rockwell's robot is an AMR solution that can transport heavy loads in factories and operate in robot fleets of over 100 units.

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.

United Robotics Group restructures

The company focuses on the healthcare industry and innovation.

Teledyne Vision Solutions: Camera manufacturer unifies machine vision portfolio

Teledyne combines the various machine vision technologies, including 1D, 2D and 3D cameras, under the umbrella of "Teledyne Vision Solutions".