New camera detects solar panel defects better

An all-weather imaging system works in any lighting conditions and uses an InGaAs detector with a very high frame rate to acquire a sequence of images of the solar panels as the electric current is applied.

Researchers have developed and demonstrated a new system that can detect defects in silicon solar panels in full and partial sunlight under any weather conditions. Because current defect detection methods cannot be used in daylight conditions, the new system could make it much easier to keep solar panels working optimally. Silicon solar panels, which make up around 90 percent of the world’s solar panels, often have defects that occur during their manufacturing, handling or installation. These defects can greatly lower the efficiency of the solar panels, so it is important that they be detected quickly and easily.

The researchers from Nanjing University of Science and Technology in China created a unique combination of new hardware and software that allows defects in solar panels to be clearly imaged and analyzed even in bright light. “Today’s defect detection systems can only be used to find defects at night or on solar panel modules that have been removed and moved inside or into a shaded environment,” said Yunsheng Qian, who led the research team. “We hope that this system can be used to help inspectors at photovoltaic power stations locate defects and identify them more quickly, so that these systems can produce electricity at their maximum levels.”

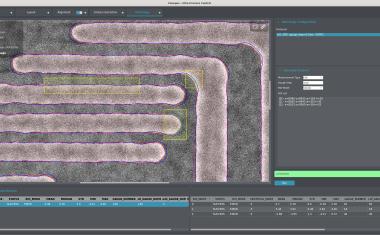

In the new work, the researchers created an all-weather imaging system that works in any lighting conditions. To make defects visible, they developed software that applies a modulated electric current to a solar panel, which causes it to emit light that turns off and on very quickly. An InGaAs detector with a very high frame rate is used to acquire a sequence of images of the solar panels as the electric current is applied. The researchers also added a filter that limits the wavelengths detected to those around 1150 nanometers to remove some of the stray sunlight from the images.

“The very fast imaging speed allows more images to be collected so that a greater number of changes between images can be distinguished,” said Sheng Wu. “The key development was a new algorithm that distinguishes the modulated and unmodulated parts of the image sequence and then magnifies this difference. This allows the defects in the solar panel to be clearly imaged under high irradiance.”

To test the system, the researchers applied it to both monocrystalline silicon and polycrystalline silicon solar panels. The results showed that the system can detect defects on silicon-based solar panels with irradiances from 0 to 1300 Watts per meter squared, which equates to light conditions ranging from complete darkness to full sunlight. The researchers are now working on software to help reduce digital noise to further improve image quality, so that the detector can collect image changes more accurately. They also want to see if artificial intelligence could be applied to the acquired images to automatically identify the types of defects and further streamline the inspection process. (Source: OSA)