Increased laser welding efficiency with patented process

Technical article by Lea Sauerwein, Christian Ebenhöh, and René Geiger in the current issue 5/2021 of PhotonicsViews: a new approach to the joining of polymers combines two different processing wavelengths with the method of quasi-simultaneous welding in order to achieve a significant reduction of welding time and enhanced weld seam quality.

Laser welding of plastics is already an extremely economical joining process in its usual form. It has been steadily gaining in importance for years and is used today in almost all industries. The experts of the Evosys team are constantly tinkering to further improve the reliability and efficiency of laser welding. With the new, patented AQW process, this has now been achieved for selected plastics.

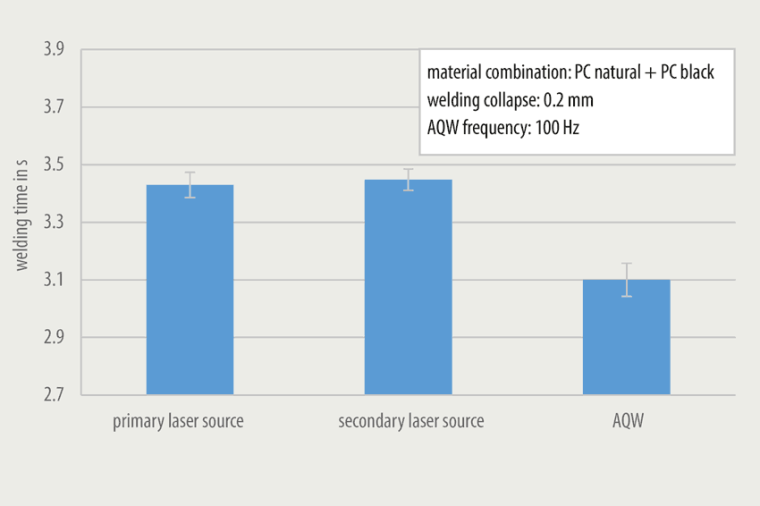

Numerous test series have shown that welding times can be significantly reduced in some cases. The process makes use of the absorption properties of the plastics and combines two different wavelengths that are alternately guided over the welding zone in a controllable pattern. Experience with advanced quasi-simultaneous welding shows an improvement in process time compared to the standard process with only one laser source. The new process can be applied to materials such as PC, but other common plastics are also conceivable in the future.

Parallel to the patent granting process, the necessary system technology for the AQW process was developed and optimized for series use. “Our customers can test the process extensively in our technical center at any time and use it later for their series production,” explains Frank Brunnecker, managing partner of Evosys Laser.

Read the full article in the October/November 2021 issue of PhotonicsViews: Lea Sauerwein, Christian Ebenhöh, and René Geiger (Evosys Laser): Evosys’ advanced quasi-simultaneous welding – A new approach to the joining of polymers, PhotonicsViews 18(5), 34 – 37; DOI: 10.1002/phvs.202100057

Company

Evosys Laser GmbHFelix-Klein-Str. 75

91058 Erlangen

Germany

most read

There’s a Large Hippo Resting in the Mud

Virtual Video Safaris for Blind and Visually Impaired People

The Rise of Photonic and Neuromorphic Computing: A New Era for AI Hardware

Computer Architectures for future data processing

Photonics West 2026: Industrial Machine Vision Takes Center Stage

The new Vision Tech Expo showcases the latest trends in AI machine vision, embedded vision, and 3D sensor technology

SPS 2025: Cautious optimism in automation

A picture of the mood of the German economy