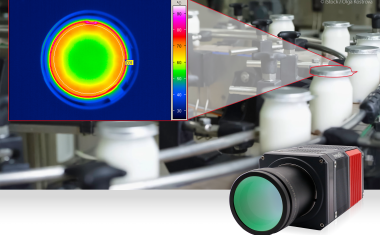

Hygienic assembly system for BV components

A hygienic complete mounting system is designed to enable food-safe and legally compliant placement of cameras in any position and orientation in food and pharmaceutical applications. To enable installers to easily comply with the specifications in every application, the manufacturer is currently preparing the full EHEDG certification of all components of the modular system.

The same hygiene requirements apply to electronic vision components used in production and packaging processes in the food or pharmaceutical industries as to plant components that come into direct contact with the product. Although cameras, line lasers or even illumination units are typically mounted above the conveyor belts and have no direct contact with the hygiene-sensitive products, there is a risk of their contamination with product residues and subsequent contamination of the germ-free areas by dripping cleaning liquids when the equipment is cleaned with steam jets. For this reason, BV components mounted in hygienically sensitive areas require suitable protective housings that ensure uncomplicated, complete cleaning and disinfection. The mounting brackets of the optical components or protective housings should also not have any designs that are difficult to clean and encourage contamination. Since there have been no system solutions for hygienic vision system mounting on the market up to now, operators have either had to resort to special designs and/or accept increased effort for cleaning and disinfecting the vision system components.

Flexible positioning under virtually any environmental conditions

With its Hygienic Building Kit, Autovimation aims to close this supply gap. The economical, individually configurable complete solution enables flexible positioning of cameras, lasers, lighting and other application-specific components under almost all environmental conditions. To this end, the kit uses a modular system that includes stainless steel mounting tubes and hygienic IP69k protective housings for cameras, lighting units and lasers, as well as hygienic 90° tube connectors, T-pieces, mounting feet and cable glands.

Easy adaptation to any mounting situation

Among the advantages of the Hygienic Building Kit is the ability to install the mounting system both upright and overhead on the ceiling. This allows the holder tubes to be attached above the conveyor using hygienic 90° tube connectors and mounting feet. The camera housings are mounted using hygienic tees that allow the housings to be aligned in any position and rotated. Simplification of the installation is provided by the cable routing inside the mounting tubes. On the one hand, the cables are thus optimally protected against mechanical effects, and on the other, their fully encapsulated routing eliminates the need for foodstuffs approval of the cables. Thus, for the application-specific configuration of the kit, users only need to shorten the holder tubes to the desired length and drill a hole for the cable passage at the point where the camera is to be placed. The other end of the cable is fed into the machine through the feet of the tube rack in a hygienically sealed manner. If it is not possible to feed the cable directly through the pipe ends, the "last meter" to the control cabinet can also be bridged with hygienic hoses.

Configuration

90° pipe connectors are used to connect the stainless steel support pipes. In addition, the hygienic tees for mounting camera and laser housings can also be used to branch the scaffold, for example, to install line lasers for laser triangulation. 90° tube connectors or hygienic tees reliably seal the joints to IP69k and, thanks to their resilient internal clamping, enable stable designs even with longer tubes and eccentric loads. Autovimation supplies the holder tubes with an outer diameter of 30 mm in lengths of 0.5 m, 1 m, 1.5 m and 2 m as standard; other dimensions are also available on request.

For fastening the stainless steel tubes to mounting or housing plates, the accessories include hygienic mounting feet for front-side bolting and tube brackets for rear-wall mounting. The rounded geometries of all mounting components, including the screws or sleeves, promote the dripping of liquids. At all joints, seals made of hygiene-compliant and chemical-resistant plastics prevent the formation of gaps or dead spaces that would promote contamination. The same applies to the blanking plugs for closing open tube ends.

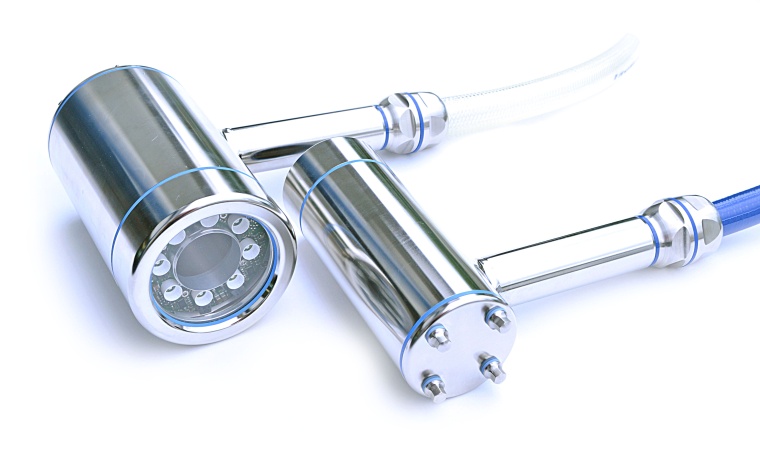

Hygienic protective housings for cameras, LED lights and lasers

For hygienic protection of cameras, LED lights and lasers, the company relies on the Hygienic Plus versions of its Dolphin, Shark and Piranha housing series for the Hygienic Building Kit. The housings are made of V4A AISI 316L stainless steel with roughness depths of < 0.8 μm to prevent germ adhesion and can be cleaned with steam cleaners thanks to their IP69k protection rating. All seals and hoses are approved for direct contact with foodstuffs in accordance with FDA and EU regulations 10/2011 and 1935/2004. The sealing materials are characterized by high chemical and temperature resistance and can withstand greases and mineral oils as well as aggressive acids and bases over the long term.

Author

Peter Neuhaus, Managing Director

Housing series

The camera housings of the Shark and Dolphin series cover a wide range of different compact camera formats. The models in the Shark series have been designed for cameras with lens diameters of up to 85 mm and housing cross-sections of up to 60 mm x 60 mm. The length of the installation space in the S, M and L housing versions is 143 mm, 193 mm and 263 mm respectively, but can be variably extended with 30 mm housing extensions if required. The ring light modules of the Meganova series with five light colors are available as an illumination solution for installation in Shark housings. With eight 1W Oslon LEDs arranged around the camera lens, they ensure optimum illumination of the monitoring area. The desired beam angles are configured at the factory with corresponding attachment lenses. Meganova's integrated flash controller allows the adjustment of pulse length, triggering behavior, current gain up to 570 percent, and many other parameters. In addition, the lighting can be connected directly to the camera's trigger output via its opto-isolated trigger input, simplifying wiring and significantly reducing response time for fast flashes.

The protective housings of the Dolphin series are ideal for smaller compact cameras. They are available in three formats for camera cross-sections from 29 mm x 47 mm to 40 mm x 40 mm and can accommodate cameras with a total installation length of up to 222 mm. For extended installation lengths, 30 mm housing extensions are also available. As with the Shark series models, a wide internal mounting area allows Dolphin housings to position any camera optic directly behind the front glass. The Quicklock/Heatguide camera mount prevents the inside of the housing from heating up by dissipating heat, keeping the camera about 15 °C cooler. Both housing series can be equipped with front windows made of FDA-compliant acrylic glass, BK7, germanium, sapphire or heat protection glass and are optionally available with rear, hygienically screwed cable entry or with side cable exit and closed rear panel. Since the versions with lateral cable outlet allow a completely internally routed cable transition when mounted via T-pieces or 90° tube connectors, the expense of hygienic cable glands is eliminated here.

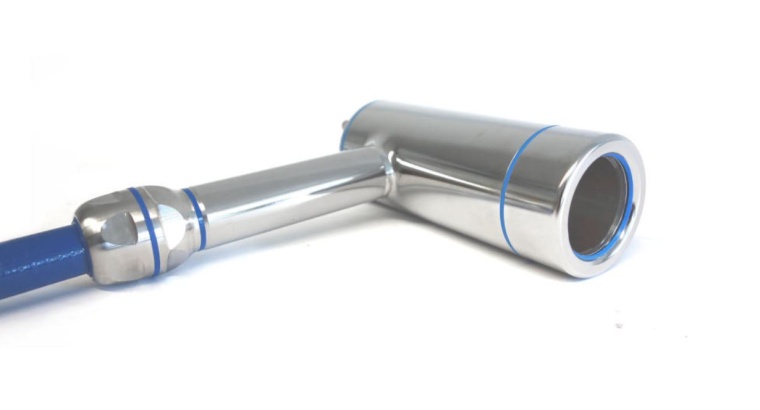

The laser safety housings of the Piranha series are used for the integration of line lasers with 19 to 20 mm diameter. For the front window with a free 28 mm diameter, which can be fixed or replaced by means of a snap ring, variants made of BK7, sapphire or acrylic with anti-reflective coating on both sides are available. The deep front cover allows lasers with or without focusing ring to be placed directly behind the front screen, with its screw cap providing free access to the focusing ring at all times. Since the Piranha housings typically use the hygienic T-pieces for mounting to the holder tubes, Autovimation supplies the models with standard V4A stainless steel cable glands on the outlet side. For deviating mounting situations Piranha is also available in a version with hygienic cable gland.