Heidelberg Instruments acquires Multiphoton Optics

With immediate effect, Multiphoton Optics GmbH is a wholly owned subsidiary of Heidelberg Instruments Mikrotechnik GmbH. One of the two managing directors of Multiphoton Optics will go to the new parent company, while the other will continue to run the company on his own.

While Heidelberg Instruments has high expectations for the further development of 3D lithography systems at the MPO site in Würzburg, the strategic merger for Multiphoton Optics primarily means access to sales potential and structures, production capacities and the global service network of the new parent company.

Dr Benedikt Stender, one of the two managing directors of MPO, will lead the company as sole managing director in the future. Dr. Boris Neubert, who was previously responsible for operations on the MPO management board, is moving to Heidelberg Instruments, where he will be responsible for integrating MPO into the new parent company.

Micro-optics using 3D lithography

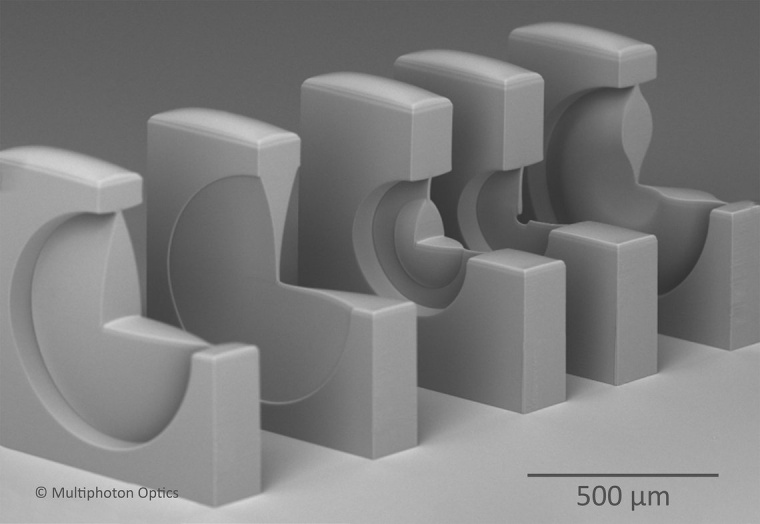

The current specialty of Multiphoton Optics (MPO) is the production of 3D free-form surfaces and structures, with a focus on micro-optics using 3D lithography. In research and development, the current focus is primarily on manufacturing processes using two-photon polymerization (2PP) and application-specific software and hardware modules.

"MPO is a pioneer of two-photon lithography and has developed a high-performance exposure system for 3D printing down to the sub-micrometer range. MPO thus fills a gap between conventional laser lithography, on which our strong core business is based, and the nanostructuring technology (t-SPL) added three years ago in the Heidelberg Instruments Nano division. Together with MPO, we will expand our position in micro-optics and structured surfaces," reports Konrad Roessler, managing director of Heidelberg Instruments.

Founded in 2013 as a spin-off from the Fraunhofer Institute for Silicate Research ISC, Würzburg-based Multiphoton Optics GmbH is a solution provider for 3D lithography via two-photon polymerization (2PP). This technology enables the production of complex functional structures in micro-optics and microsystems technology, optical interconnect technology, micromechanics and biomedical engineering. The LithoProf3D-GSII modular 3D printing platform enables high-precision manufacturing of complex microstructures with very high throughput.

Active in the development and production of high-precision photolithography systems and nanofabrication tools, Heidelberg Instruments (HIMT) has more than 1,000 systems installed. HIMT systems are used in industry and research. They are used for efficient direct exposure, but also for the fabrication of photomasks for various industrial sectors, including semiconductors, quantum computing, photonics, 2D materials, IoT, and many related application fields.