Fraunhofer IPM: Research project for autonomous inspection system

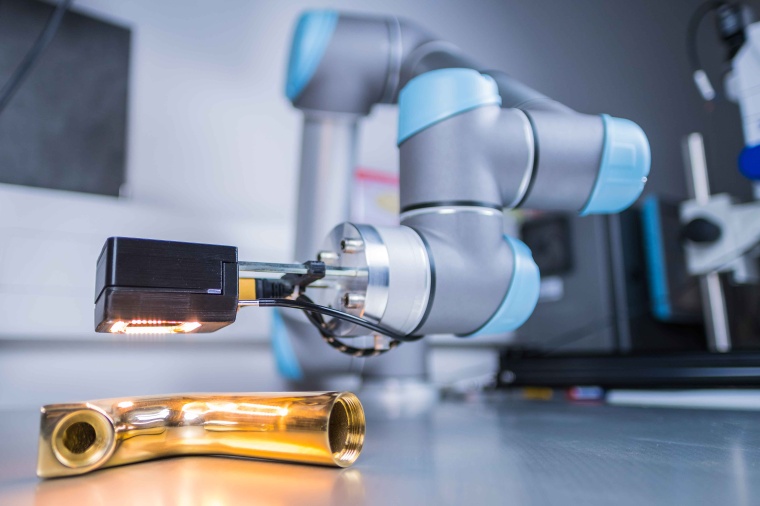

As part of the Spot research project, Fraunhofer IPM is working with partners to develop an optical inline measurement system that evaluates and adapts itself largely autonomously with regard to the respective component and the associated inspection requirements on an AI basis.

The envisaged solution, which is being developed by the Fraunhofer Institute for Physical Measurement Techniques IPM with numerous partners, consists of three parts:

- First, of an optical sensor that checks component surfaces for defects and particles directly after cleaning,

- secondly, cleaning systems for the qualified cleaning of complex components and and

- thirdly, a control system that evaluates and adapts the cleaning and measuring system largely autonomously with regard to the individual components and the associated inspection requirements on an AI basis.

At Spot, the detection and classification of particulate contamination and defects on component surfaces will enable adaptive photonic surface testing with adaptive image evaluation. The optical image generation is realized with the help of adaptive light field control, the automatic image analysis with the help of AI methods. The adaptive light field ensures that the optimal illumination is used for each component surface. This ensures that defects and particles on the component can be inspected safely, regardless of its geometry and reflective properties.

The project partners are:

- PI Innovation (Coordinator)

- Hexagon Metrology Vision

- Höckh Metall- Reinigungsanlagen

- LPW Reinigungssysteme

- Gläser

- Iconpro

- Fraunhofer IPM

- TU Dortmund, Institut für Produktionssysteme (IPS)

The users are:

- Audi

- Hansgrohe

- MTU Aero Engines

- Sprintbox

- ZF Friedrichshafen