Formula Student team relies on Tox

Specialist for sheet metal joining processes supports Esslingen University with clinch tools

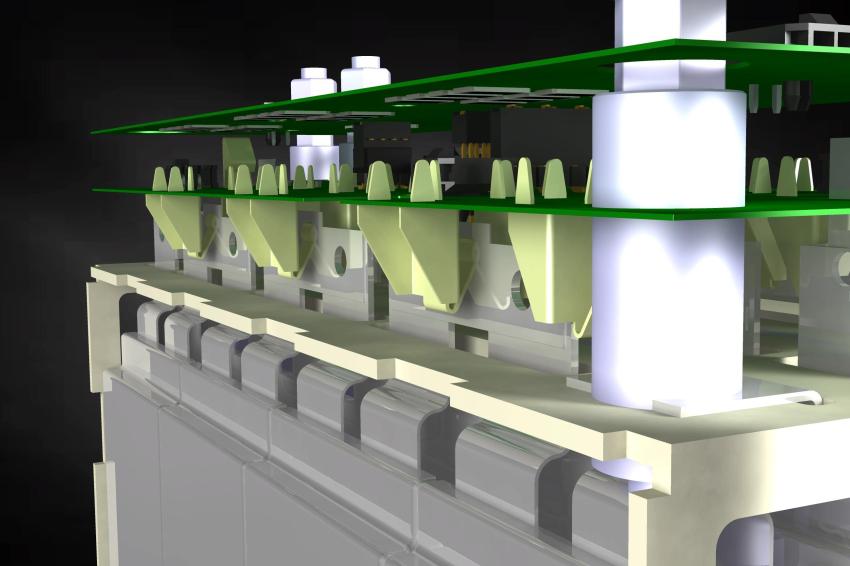

In the Formula Student competition, students develop, construct and manufacture a racing car on their own and compete against each other in international competitions. The Formula Student Electric team at Esslingen University was founded in 2011 under the name E.Stall. The team of around 30 is currently manufacturing its third all-wheel drive vehicle. A crucial component for the successful performance is the traction battery. It depends on whether the driver has enough power available to assert himself against the competition. The high-voltage battery installed in the car has a maximum voltage of 600 volts and a capacity of 7.6 kilowatt hours. It is divided into twelve modules for good and safe handling. The individual cells are connected in series with so-called busbars through which currents of more than 150 amperes flow.

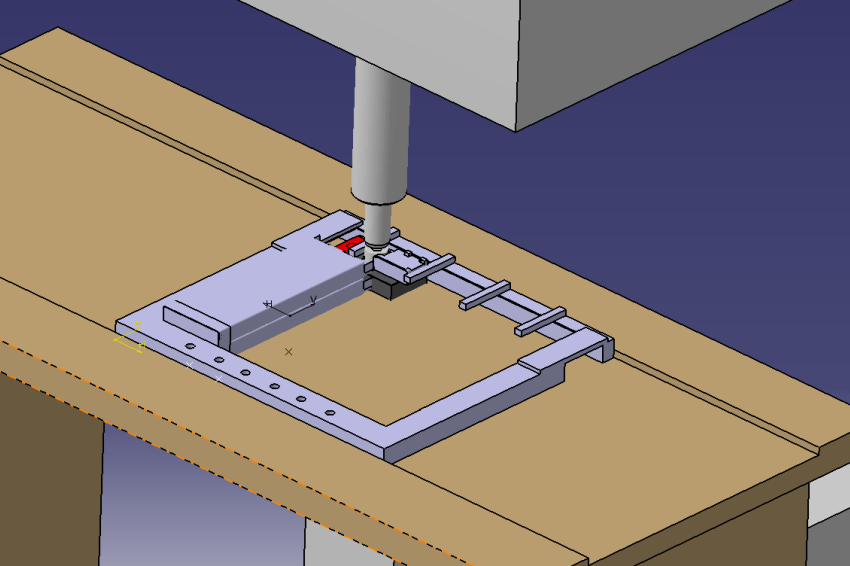

To connect the cells using clinch points, the students used a clinch tool provided by Tox Pressotechnik. Clinching is a connection technology that is easy to implement without additional elements or auxiliary parts: In a cold forming process, several layers of sheet metal - in this case four layers had to be connected to each other - are created into a snap-button-like connection. With the help of this technology, the E.Stall team was able to massively reduce the construction time and increase process reliability. The Tox specialists supported the students with their know-how and optimally designed the electrical eClinch connection.

Contact

TOX Pressotechnik GmbH & Co. KG

Riedstr. 4

88250 Weingarten

Germany

+49 0751 5007 0

+49 751 52391