Embedded Vision: Fast Time to Market with Low Hardware Costs

Interview with Product Manager Magalie Haida from Automation Technology

nspect talked with Magalie Haida from Automation Technology about the development of embedded vision in machine vision. She explained the company’s approach, including their focus on the US market and the significance of their embedded vision solutions like the IRSX-I thermal camera. Haida also provides insights in potential applications and technological advancements driving Automation Technology’s future plans, including a new camera series in thermal embedded vision.

inspect: Embedded vision is considered one of the growth areas of industrial machine vision. How is this area developing at Automation Technology?

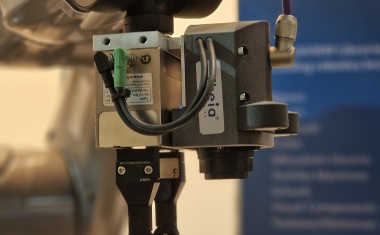

Magalie Haida: We use embedded vision at several stages of the image processing chain. In our 3D sensors, for example, embedded vision already begins on the sensor chip. With the IRSX-I camera, on the other hand, the entire software concept can be described as embedded vision, as the complete machine vision solution runs on the camera in addition to the image pre-processing. We are therefore observing strong growth in various areas of embedded vision – from on-chip processing to smart camera solutions.

inspect: How important is the US business with the parent company in northern Germany?

Haida: The US business and growth in the North American market is hugely important to the parent company in Northern Germany. The office in the US is the first subsidiary of its kind for AT where there were focused investments for a quick ramp up in the team. There was research and careful consideration on choosing the US as a first expansion location. It was determined that the available market and appreciation for German engineering was so high that it was a logical step. It was also understood that to effectively do business in North America, local team members are required. This is not just to address communication and time zone needs but also to provide the necessary full customer experience.

inspect: How is the US business developing?

Haida: Even with the market in several industries still being a bit down, our business in the US is developing really well. Over the last year we have had several potential customers testing and evaluating our sensors for new systems. The feedback has been fantastic on the performance and reliability, and we are entering the next stages of system development.

inspect: What are the major areas of focus?

Haida: The major areas of focus now that we have a great, complementary team, is on getting our name and values known more in our target applications. We have some exciting marketing initiatives coming out this year including some great video content. We will also expand our presence at trade shows and continue to add more informative content to our new website.

inspect: With the IRSX infrared camera, Automation Technology also offers a device with integrated image processing hardware. Why is AT focusing on embedded vision here instead of separating acquisition and processing?

Haida: With the embedded vision approach, we enable our customers to achieve a fast time-to-market with low hardware costs and no software development effort. We are also convinced that established IoT interfaces such as OPC-UA, MQTT and fieldbus protocols such as Ethernet/IP and Profinet allow embedded vision devices to be efficiently integrated into customer applications. In our opinion, embedded vision solutions are therefore the method of choice, especially in distributed applications.

inspect: What are the benefits of the smart infrared camera for embedded vision?

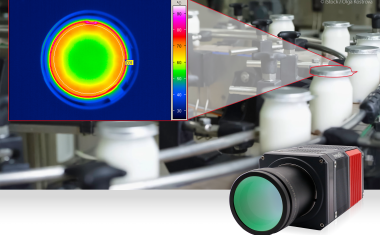

Haida: The IRSX-I infrared camera from AT completely redefines the benchmark for efficiency and integration for embedded vision systems by being designed as a complete all-in-one solution. Without any external hardware, the IRSX-I records measurement data, and processes and evaluates it directly on the camera. The data is then evaluated and analyzed quickly and effectively using a measurement plan (job) stored in the camera, which can be configured using the web-based job editor.

Furthermore, integration into existing system landscapes is child’s play thanks to the standardized GenICam interface and other IoT protocols such as Modbus or REST-API, which makes the camera particularly attractive for a wide range of applications. Configuration of the camera parameters is effortless via a web-based interface, so no additional software is required.

inspect: In which applications is this smart camera mainly used?

Haida: Thanks to the unique adaptability and flexibility of the IRSX-I, as well as its reliable industrial suitability, it can be used in a wide range of embedded vision applications, especially when it comes to temperature monitoring or quality control. One application for which the smart infrared camera from AT is particularly suitable, for example, is flare monitoring. This application involves monitoring the constant burning of a pilot flame in industry to ensure that no harmful gases are released into the atmosphere. Originally, companies installed temperature sensors at the edge of the chimney for flare monitoring. With the IRSX-I, however, this is no longer necessary as the infrared camera can monitor the flare remotely [watch the video] and, in the event of a failure, sends a signal directly to the PLC control system thanks to its smart features. The situation is similar with the temperature monitoring of transformer stations [watch the video]. If irregularities occur here, the smart IRSX-I immediately triggers an alarm so that fires don’t start in the first place.

inspect: Where do you see the greatest development potential (application-related) for embedded vision?

Haida: With thermal cameras we see the greatest potential in cloud-based thermal applications for condition monitoring of industrial equipment, for early fire detection of storage areas, for battery assembly and storage and for classical applications in steel industry and petrochemical applications.

inspect: Where do you see the greatest technological potential?

Haida: We see the greatest potential above all in the consistent use and implementation of the IoT standards mentioned above, both in embedded devices and in higher-level applications. There is a clear trend towards using embedded devices in the form of cloud solutions in distributed applications.

inspect: What can we expect from AT in this respect?

Haida: We are continuously working on expanding our IoT platforms to better support established standard protocols and further expand the range of compatible third-party solutions.

inspect: What new products will AT be presenting this year?

Haida: We will see new releases of our IRSX-I apps and also plan to launch a new camera series focused on thermal embedded vision.

Author

David Löh, Editor-in-Chief of inspect