Easier production of photonic MEMS

New approach could enable more efficient fiber-optical telecommunications and future quantum computers

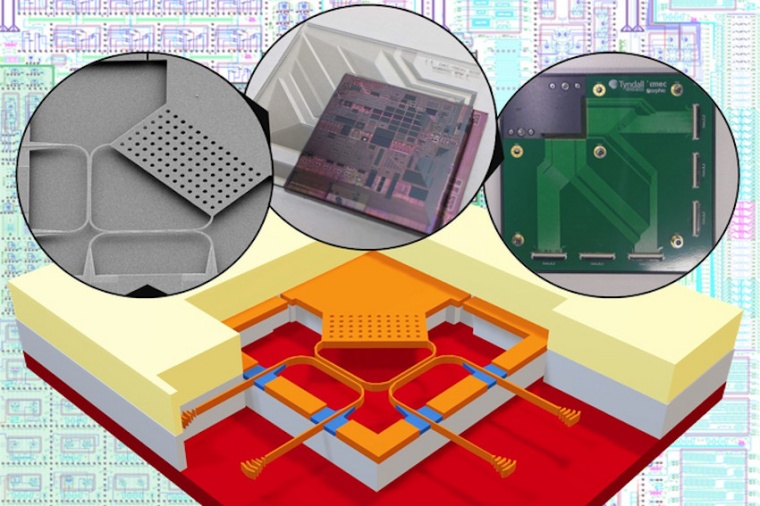

A team of researchers led by Niels Quack, University of Sydney, has developed a new technology to combine optics and micro-electro mechanical systems (MEMS) in a microchip, paving the way for the creation of devices like micro-3D cameras and gas sensors for precision air quality measurement, including their use in mobile phones. The new microfabrication process builds on silicon photonics and uses semiconductor manufacturing techniques to enable a new, more energy-efficient generation of devices for fiber-optical communications, sensors and even future quantum computers.

Quack said that the photonic MEMS are unique in that they are compact, consume very little power, are fast, support a broad range of optical carrier signals and have low optical loss. “This is the first time that nano-electro-mechanical actuators have been integrated in a standard silicon photonics technology platform,” Quack said. “It is an important step towards mature large-scale, reliable photonic circuits with integrated MEMS. This technology is being prepared for high-volume production, with potential applications in 3D imaging for autonomous vehicles or new photonic assisted computing.”

“Current similar technologies consume a lot of power and occupy a large area on-chip. They also have high optical losses. This makes the integration of a large number of components on a single chip challenging,” he said. “Our silicon photonic MEMS technology overcomes these shortcomings, providing a route for efficient scaling of photonic integrated circuits. The technology will advance knowledge in the field of micro- and nanofabrication, photonics and semiconductors, with a wide range of applications. These include beam steering for LIDAR 3D sensing in autonomous vehicles, programmable photonic chips, or information processing in quantum photonics.” (Source: U. Sydney)