Deep OCR on the Edge: No buzzword bingo, but real customer benefit

Optical character recognition with AI support

Converting text from camera images into machine-readable data is anything but trivial. If an ‘O’ becomes a ‘0’ or an ‘A’ becomes a ‘4’, this quickly leads to misunderstandings and errors. At best this is unpleasant, at worst costly - making it more important to choose an OCR system that is as powerful as possible. A prototype clearly demonstrates how, thanks to the collaboration between two highly specialised companies, very reliable and fast text recognition with AI can be implemented directly on a camera in the future.

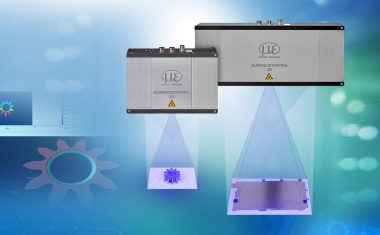

The demo system is the result of IDS's combined expertise in the field of industrial cameras and Denkweit's AI algorithms. “At product level, we are demonstrating the combination of our intelligent IDS NXT malibu industrial camera and the Deep OCR solution with Denknet,” explains Patrick Schick, Product Owner at IDS. Thanks to an Ambarella SoC (System on Chip) integrated into the camera, it is possible to perform AI-based text and character recognition directly on the camera. As soon as the product is ready for series production, customers will be able to use the technology ‘out of the box’ without having to connect an industrial PC.

He continues: “The trend is towards making AI smaller, faster and cheaper to implement. Our demo system achieves speeds in the low millisecond range both when searching and finding the text blocks and when reading the text. The prototype shows how high-quality OCR can be performed quickly on a small embedded device.”

When mix-ups must not be an option

Optical character recognition is still one of the most difficult disciplines for machine intelligence in image processing. The pure diversity of possible characters and methods used to apply characters to a wide variety of surfaces gives an idea of the challenges involved. Converting such complex visual data into clear, structured texts is no easy task – especially when dirt, reflections or material shape errors also come into play. Overlapping or incomplete characters, as well as a generally low pixel resolution of the image data, can mean that characters cannot be reliably distinguished from one another by man or machine.

This is precisely where Denknet, the AI vision solution for customised image analyses, can help. In addition to leading AI technology, users have access to an extremely high-performance and constantly evolving OCR model. Thanks to advanced deep learning algorithms, characters can be accurately identified and interpreted even under difficult conditions. It doesn't matter whether Denknet has to deal with distorted fonts, low-contrast surfaces or different lighting conditions – this system works with a high precision. It can read text from a variety of surfaces, including packaging materials, labels and documentation.

Single-device solution: Seamless integration in industrial cameras from IDS

The combination of Denknet OCR and industrial cameras from IDS Imaging Development Systems scores particularly highly in terms of the simplicity with which an OCR application can be set up and used.

In real-world applications, the single-device solution can, for example, help to make the handling of goods in the production process more reliable. Processes such as sorting, inventory management and shipment tracking can also benefit from automatic text recognition ‘on the edge’.

Another positive aspect of a good OCR model is its ability to recognise not only individual characters, but also the relationships between them – in the case of character sequences, such as serial numbers or words – and to take this knowledge into account when recognising characters. The better the OCR can predict subsequent characters and weight the reading result accordingly, the more robust and precise special applications can be solved with it.

Continuous optimisation for future-proof processes

Denknet OCR is designed to learn and adapt over time, improving accuracy with each iteration. This means that Denknet OCR continues to evolve without the need for constant manual updates.

All development steps are strictly versioned so that application developments can fall back on defined versions. However, you also have the option of updating to a new, improved version to ensure versatile and robust reading at all times. For quality assurance purposes, the performance and reproducibility of the trained networks can be tested and verified in a quality centre against sample data sets before a production system is updated with new software.

But what if a sign cannot be recognised after all?

Then it is important that fine-tuning is not simply a matter of ‘re-learning’ the network. Consider, for example, that the OCR model has been trained with 2 million images and the user now wants to teach the OCR model something new with a few images of their own. What weighting should be given to such information in the model in order to make a difference but not change everything? This is exactly where a lot of expertise is required from the provider to expand the AI in such a way that the previous stable recognitions are not negatively affected by such an adjustment.

An example: For some reason, an OCR has problems with numbers and the user only annotates numbers during the training process, never letters. The aim is to use intelligent ‘knowledge backup’ to prevent this network from only being able to successfully read numbers at some point because it thinks it doesn't need to read letters.

The Denk Vision AI Hub therefore generates suitable artificial data for all new image data when fine-tuning the Denknet OCR in order to further train and weight the network to the right extent. This prevents the OCR from losing its previous capabilities, no matter how long it continues to be trained. At the same time, ‘retraining’ remains easy for the user of the Vision AI Hub and fast and performant thanks to cloud-based training in the background. In the best-case scenario, the basic skills of the OCR are so good that users no longer need to retrain at all.

Company

IDS Imaging Development Systems GmbHDimbacher Str. 10

74182 Obersulm

Germany

most read

There’s a Large Hippo Resting in the Mud

Virtual Video Safaris for Blind and Visually Impaired People

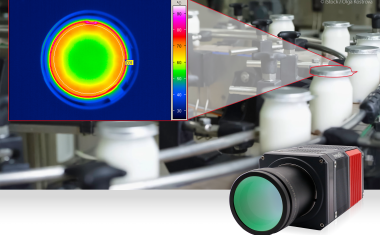

MWIR system camera for continuous industrial operation

Entry into infrared imaging

Productivity Boost for the Frontline

Machine Vision and AMRs as Part of AI-Driven Strategies in Manufacturing and Warehouse Operations