Cooking with lasers

Laser based method retains more moisture, and creates an entirely new way to cook a tasty meal allowing individuals to more precisely customize their meals.

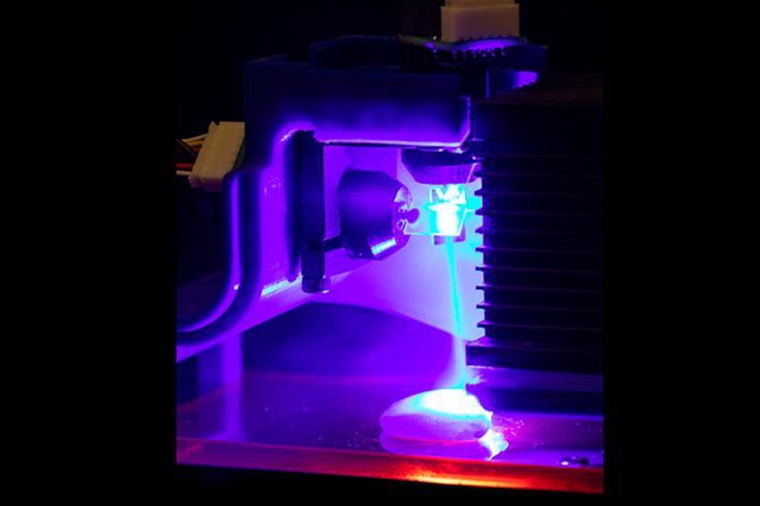

Imagine having your own digital personal chef; ready to cook up whatever you want; able to tailor the shape, texture, and flavor just for you; and it’s all at the push of a button. Columbia engineers have been working on doing just that, using lasers for cooking and 3D printing technology for assembling foods. Under the guidance of Hod Lipson, the “Digital Food” team of his Creative Machines Lab has been building a fully autonomous digital personal chef. Lipson’s group has been developing 3D-printed foods since 2007. Since then, food printing has progressed to multi-ingredient prints and has been explored by researchers and a few commercial companies.

“We noted that, while printers can produce ingredients to a millimeter-precision, there is no heating method with this same degree of resolution,” said Jonathan Blutinger, a PhD in Lipson’s lab who led the project. “Cooking is essential for nutrition, flavor, and texture development in many foods, and we wondered if we could develop a method with lasers to precisely control these attributes.” Now, the team explored various modalities of cooking by exposing blue light (445 nanometers) and infrared light (980 nanometers and 10.6 micrometers) to chicken, which they used as a model food system. They printed chicken samples (3 millimeters thick by ~1 squareinch area as a test bed and assessed a range of parameters including cooking depth, color development, moisture retention, and flavor differences between laser-cooked and stove-cooked meat. They discovered that laser-cooked meat shrinks 50 % less, retains double the moisture content, and shows similar flavor development to conventionally cooked meat.

“In fact, our two blind taste-testers preferred laser-cooked meat to the conventionally cooked samples, which shows promise for this burgeoning technology,” Blutinger said. While Lipson and Blutinger are excited about the possibilities of this new technology, whose hardware and software components are fairly low-tech, they note that there is not yet a sustainable ecosystem to support it. Lipson states that “what we still don’t have is what we call Food CAD, sort of the Photoshop of food. We need a high level software that enables people who are not programmers or software developers to design the foods they want. And then we need a place where people can share digital recipes, like we share music.” Still, says Blutinger, “Food is something that we all interact with and personalize on a daily basis – it seems only natural to infuse software into our cooking to make meal creation more customizable.” (Source: Columbia U.)

Link: Creative Machines Laboratory, Dept. of Mechanical Engineering, Columbia University, New York, USA

most read

Qioptiq Photonics becomes Excelitas Germany

The renaming is part of the global consolidation of the Excelitas Group.

MVTec Innovation Day 2026: Exchange and insights into machine vision

This event, now in its eighth year, offers the machine vision community a platform for networking and professional exchange.

Lapp Group takes over JJ-Lapp completely

JJ-Lapp will now become a wholly-owned subsidiary of the Group, with financial details remaining confidential.

5 robotics trends for 2026

The International Federation of Robotics reports on the five most important trends for the robotics industry in 2026.

Purdue University, Rittal and Eplan work together

As part of this partnership, Purdue will open two exclusive laboratories.