AI and Optics: Working Hand in Hand for Enhanced Quality Control

Potential of artificial intelligence in machine vision

Lowering costs while increasing product quality: AI-based pattern recognition and analysis is becoming a game changer in manufacturing quality control. This is especially true when combined with optical techniques such as polarization imaging and infrared hyperspectral analysis.

Optical methods with computer-assisted image analysis play a key role in automating quality control. The integration of AI into industrial image processing is currently revolutionizing this field. This shift is driven by clear advantages: in conjunction with recent advancements in optics, such as IR hyperspectral analysis and polarization imaging, significant cost and time savings can be achieved compared to traditional methods. Another major benefit of AI-supported imaging systems is their precision. These systems can detect even the smallest deviations from target specifications – anomalies that are often missed by conventional methods.

While traditional machine vision in quality control identifies only existing defects, AI-enabled systems can go further, predicting potential future issues by analyzing large data sets and generating timely alerts. These insights can be integrated into production planning and management systems, enabling not only product improvements but also minimizing equipment downtime. This, in turn, extends the lifespan of production systems.

The collected data also supports companies in making their production processes more flexible and reducing manufacturing costs – an especially critical advantage for high-wage countries like Germany in the global marketplace.

Alignment of Optical Components and AI

The success of these systems depends on the careful alignment of optical system components, including lighting, lens selection, and image sensors, with the AI software. For instance, when inspecting large objects like injection-molded or stamped parts, the seamless interaction of components significantly enhances the performance of neural networks. Similarly, for processes with long or extended cycles, AI excels by analyzing data patterns to deliver highly accurate results in a short amount of time.

Technologies for AI-assisted Optical Systems

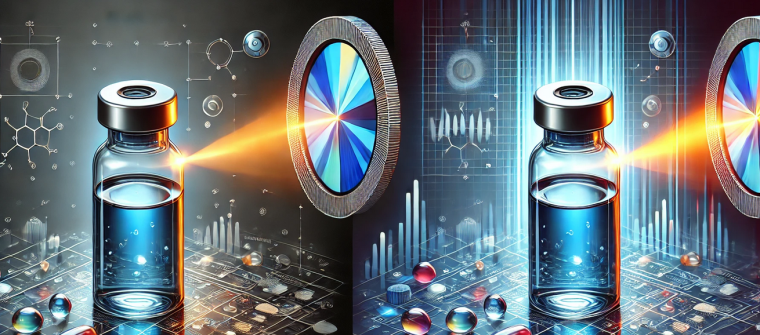

Among the technologies providing competitive advantages in AI-assisted optical systems for automated production processes are spectral imaging and polarization optics.

Spectral imaging leverages the unique reflection and transmission properties of materials across the electromagnetic spectrum for identification and measurement. This approach is particularly effective in the shortwave infrared (SWIR) range, where materials often transition between reflective and transparent states. This capability enables exceptional analytical insights. However, the technique requires high-quality optics with advanced features such as chromatic correction, excellent stray light management, and high transmission efficiency.

Recent advances in sensor technology further enhance the utility of spectral imaging. Modern SWIR sensors, particularly those based on gallium arsenide (GaAs), offer both high sensitivity and exceptional resolution. Their compact size and low energy consumption make them suitable for mobile applications and allow for the development of space-efficient devices.

Polarization Imaging is another innovative technique for optical quality control. It exploits the property of electromagnetic waves – including light – to oscillate within a specific plane of polarization. Using polarizers, polarized lighting, and specialized polarizing filters, this method provides insights into defects or inclusions in glass or transparent plastics that are otherwise invisible. These insights help identify stresses within materials under inspection. Additionally, polarization imaging opens up valuable new possibilities for surface inspections.

AI and Optical Methods Increase Efficiency

The combination of AI and optical methods also delivers another critical advantage: time savings. In industrial production, short cycle times and efficient processes are vital competitive factors that drive higher productivity. Traditional methods often require separate testing procedures for material properties, dimensional accuracy, and surface characteristics. Multi-aperture lenses, however, allow for these inspections to be consolidated. These lenses simultaneously supply multiple image sensors with data from various spectral ranges, enabling comprehensive quality checks in a single pass.

Similarly, multi-measurement-point lenses enable the integration of multiple measurement points into a single testing station using only one camera sensor. This reduces the number of cameras and sensors required for quality control, simplifying integration into existing production lines.

Company

Vision & Control GmbHMittelbergstr. 16

98527 Suhl

Germany

most read

There’s a Large Hippo Resting in the Mud

Virtual Video Safaris for Blind and Visually Impaired People

SPS 2025: Cautious optimism in automation

A picture of the mood of the German economy