Digital Tools, Design Software, Simulations

The special e-issue 4/2021 August/September 2021 of PhotonicsViews magazine has started a series of digital tools or software that eases your life as a photonics professional by either helping you with your system design or during the manufacturing process or when purchasing components.

The special e-issue 4/2021 August/September 2021 of PhotonicsViews magazine has started a series of digital tools or software that eases your life as a photonics professional by either helping you with your system design or during the manufacturing process or when purchasing components.

Read this issue’s articles as single PDFs or browse the entire issue’s e-paper.

Further entries were added from issues of the following years. To be continued …

(Image source: Shutterstock / Gorodenkoff)

Additive Manufacturing

Simufact Welding

simufact.com/simufactwelding-welding-simulation.html

Directed energy deposition (DED) is a powerful additive manufacturing technique that combines a high degree of freedom in design with relatively high deposition rates that can increase throughput. DED structures are created by repeatedly depositing weld beads from powder or wire feedstock, which also makes it an attractive technique for hybrid manufacturing because features can be added to a base component. However, the numerous heating and cooling cycles involved in the deposition process result in a complex thermal history that can entail distort the entire component.

Article: Beatrix Elsner (Hexagon Manufacturing Intelligence), Frank Silze (OSCAR PLT), and Axel Marquardt (TU Dresden): IMProVing directed energy deposition – Industry collaboration overcomes distortion in new DED additive manufacturing processes with simulation, pp. 40–42; DOI: 10.1002/phvs.202100052

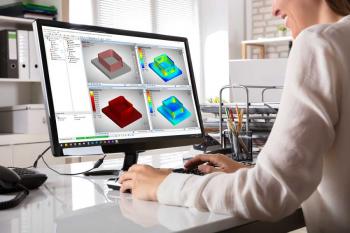

Image: Simufact Welding graphical user interface (GUI) (Source: Hexagon)

Machine and Control Technology

Photonic Elements

pulsar-photonics.de/laser-anlagenbau/maschinensoftware

As part of the German government-funded joint ‘Additive laser process for the production of tribological multifunctional layers for energy-efficient systems’ project, or ATSM for short, the Fraunhofer Institute for Laser Technology (ILT) and Eloxalwerk Ludwigsburg Helmut Zerrer GmbH (ELB), together with Pulsar Photonics, developed a new and innovative process for the laser-based production of tribological multilayer systems on lightweight components, including control software.

Article: One software and two lasers for three layers – The ATSM project developed an optics module and control software for laser-based production of tribological multilayer systems. PhotonicsViews has the interview with project manager David Pallasch, PhotonicsViews 19(5), pp. 22–23

Read also: One software and two lasers for three layers, WileyIndustryNews.com, 23 November 2022

Image: David Pallasch (left) discussing details of the beam alignment module (BAM) and the optic setup of a laser processing machine with a customer before final assembly in Pulsar Photonics’s new location in Aachen-Verlautenheide. (Source: Pulsar Photonics)

“Internet of Production” / Kubernetes

iop.rwth-aachen.de

Software Tools for Laser Material Processing

ilt.fraunhofer.de/en/media-center/brochures/…

In the Cluster of Excellence “Internet of Production” (IoP), two hundred scientists at RWTH Aachen University in co-operation with Fraunhofer ILT have set up a data center for controlling and monitoring industrial processes. The concept for this is based on a project for controlling laser systems developed at the Fraunhofer Institute for Laser Technology ILT and uses the open source software Kubernetes. A corresponding system has been running successfully at the institute for two years, and with it the institute can automatically and remotely install the software for new lasers in just a few minutes.

Article: Controlling 100 lasers automatically via the cloud – Using open-source cloud technology to manage laser manufacturing software, pp. 57–59.

Image: The Kubernetes software is used, for example, to control ultrashort-pulse laser systems. The scientists are currently researching the automatic evaluation of measurement data. (Source: Fh. ILT)

Machine Vision

VGSTUDIO MAX

volumegraphics.com/en/products/vgsm.html

Because of their high power density, rechargeable lithium-ion batteries are subject to strict quality monitoring. Industrial computed tomography is increasingly being used to detect any defects before delivery or during production.

Article: Intelligent quality assurance for batteries – Computed tomography detects defects in modern lithium-ion batteries, pp. 49–51, by Richard Laepple on behalf of Volume Graphics GmbH

Image: 3D visualization of a CT scan of a battery pack containing a prismatic cell rendered with VGSTUDIO MAX. (Source: Volume Graphics / Waygate Technologies, formerly GE Inspection Technologies)

Measurement Technology

Metrology Software

zygo.com/products/metrology-systems/…

When looking at the place of metrology in the ‘fourth industrial revolution’, it is interesting to ponder whether industry 4.0 is being driven by developments in metrology or metrology developments are being driven by Industry 4.0.

Article: Peter J. de Groot & Michael Schmidt (Zygo Corp.): Metrology & Industry 4.0 – Deploying optical technology and process control solutions to the smart factory floor, pp. 73–75; DOI: 10.1002/phvs.202100053

Image: The future of advanced manufacturing relies on greater integration of precision metrology with production quality control. (Source: Zygo)

Optical Components and Systems

COMSOL Multiphysics®

comsol.com

Optical fiber networks, which make up the backbone of the internet, rely on many electrical signal processing devices. Nanoscale silicon photonic network components, such as phase shifters, could boost optical network speed, capacity, and reliability. To design these small but powerful devices, a team at the Swiss Federal Institute of Technology Lausanne uses simulation to optimize both optical and electromechanical performance.

Request a COMSOL® software demonstration at comsol.com/request-a-demo

Article: Alan Petrillo (Comsol): Photonic devices for future network designs

Designing a silicon photonic MEMS phase shifter with simulation, PhotonicsViews 19(4), August 2022, pp. 37 – 39; DOI: 10.1002/phvs.202200035

Image: Simulation showing deformation of the movable waveguide support structure. The thin elements that suspend the movable waveguide will flex in response to an applied voltage. (Source: EPFL, CC BY 4.0)

PanDao – from optics to fabrication

pandao.ch

It takes optical systems such as sophisticated car headlights, telescopes or endoscopes to apply light as a tool, for example to see in the dark, to detect rocks in outer space or stones in a human kidney. As the accuracy of the usage of light tools is increasing rapidly, the quality of optical systems has to follow accordingly. So the process of generating optical systems needs to be optimized to enable the optimum transfer of accuracy and quality to all subsequent entities in the creation process, right from the initial application idea through to final acceptance testing.

Register for a free and personal online demonstration of the tool or for a free trial. Also: use the new design-to-fabrication service, where the experts analyze your lens with the PanDao tool and report to you – ask for a quotation.

Article: Oliver Fähnle, Rolf Rascher, and Marco Tinner (PanDao / OST – Eastern Switzerland University of Applied Sciences): Optical fabrication chain design – By analyzing lens data during optics design, the optimal optical fabrication chain can be determined, pp. 43–45; DOI: 10.1002/phvs.202100051

Image: Optical fabrication chain design within reach thanks to the online tool. (Source: PanDao)

Simcenter is a flexible, open, and scalable portfolio of the best predictive simulation and test applications that support you at every step in your digital journey. Simcenter is a key component within the Xcelerator portfolio, allowing engineers to generate a set of ultrarealistic, multiphysics models and data that can predict real product behavior. By providing insight into the real-world performance of a product or a process, Simcenter allows you to accelerate innovation over the entire lifecycle.

Article: John Parry (Siemens Software): Mind the gap – Using thermal simulation software to analyze cooling mechanisms of pluggable optics modules, pp. 68–72; DOI: 10.1002/phvs.202100049

Image: Siemens PLM – electronics digitalization (Source: Siemens Digital Industries Software)

Optics Design

Zemax OpticStudio Professional

zemax.com/pages/opticstudio

UpNano combined their additive manufacturing system NanoOne with Ansys Zemax' virtual prototyping technologies to help companies optimize polymer lens development and achieve high-resolution precision at an unprecedentedly tiny scale. The high-powered lasers and data-driven system design enhancements yielded rapid fabrication techniques at the nano, micro, meso, and macro range.

Article: Software integration for 3D lens prototyping and complex lens analysis workflows – Ansys Zemax solutions enable rapid prototyping and yield optimization for UpNano’s in-house and external projects, PhotonicsViews 19(5), pp. 40–43; DOI: 10.1002/phvs.202200038

Image: Microlenses, surface elements, or roller bearings can be produced with two-photon lithography across twelve orders of magnitude. Here: micron range (Source: UpNano)

3DOptix

www.3doptix.com

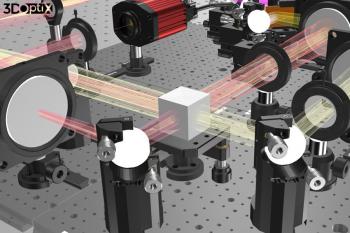

In a stark contrast to traditional optical design and simulation software, 3DOptix offers a free, easy-to-use, cloud-based, collaborative optical design and simulation software. It includes a suite of discovery tools, such as off-the-shelf optical element search, Filter finder tool, professional drawing/media capabilities, educational walk-me, and live mode. The modern UI/UX design allows for a steep learning curve catering to both experienced optical designers and novices.

Article: Haim Suchowski (3DOptix / Tel Aviv University): Cloud-based simulation tools for streamlined optical design – 3DOptix is a free, easy-to-use, cloud-based optical design and simulation software which includes a suite of discovery tools and drawings, pp. 46–48; DOI: 10.1002/phvs.202100054

Read also: 3Doptix’ cross-vendor optics discovery portal, WileyIndustryNews.com, 24 March 2021

Image: “The Future of Optical Design” (Source: 3DOptix)

‘First time right’ – B-PHOT / Vrije Universiteit Brussel

first-time-right.b-phot.org/webapps/…

Today’s design of optical systems relies largely on efficient ray tracing and optimization algorithms. Such a ‘step-and-repeat’ approach to optical design typically requires considerable experience, intuition, and trial-and-error guesswork. Brussels Photonics researchers have developed a design method that allows highly systematic generation and evaluation of directly calculated freeform design solutions and enables a rigorous, extensive, and real-time evaluation in solution space. Readers have the opportunity for hands-on freeform design experience via an open-access web application.

Article: Fabian Duerr & Hugo Thienpont (B-PHOT / VUB): ‘First time right’ freeform optics – A systematic and highly effective tool to design imaging systems from scratch, pp. 52–56, DOI: 10.1002/phvs.202100047

Read also: “First time right” freeform optics, WileyIndustryNews.com, 5 July 2021

Image: Included freeform design web app. A how-to-use manual is provided in the Supplementary Information document of article [1]. (Source: B-PHOT / VUB)

COMSOL Multiphysics®

comsol.com

Numerical simulation of optical components and photonic devices is an essential step in the design of new products and the optimization of existing designs. Fast and cost-effective simulation can substantially reduce the amount of experimentation and prototyping required in the product development cycle.

Request a COMSOL® software demonstration at comsol.com/request-a-demo

Article: Phillip Oberdorfer, Yosuke Mizuyama, and Christopher Boucher (Comsol): Deeper insights, better designs – less prototypes: How state of the art multiphysics simulation helps to understand, predict, and optimize photonics processes and devices, pp. 62–67; DOI: 10.1002/phvs.202100050

Image: Lens system (Source: Shutterstock / Denniro)

Production Safety

Cobot Designer

cobotplaner.de

The safety of people interacting with robots has top priority, especially when humans and robots are working side by side instead of being separated from each other by safety fencing. The Fraunhofer Institute for Factory Operation and Automation IFF’s web-based design tool helps companies design their cobots. The Cobot Designer helps minimize the risk of accidents and increases employee safety. The tool is available as a free web application.

Article: Web-based design tool for better job safety – Safe human-robot collaboration, pp. 60–61

Image: With the ‘Cobot Planner’, human-robot workplaces can be planned easily and safely. (Source: Fh. IFF)