New method for 3D quantitative phase imaging

09.09.2024 - All-optical multiplane design eliminates the need for digital phase recovery algorithms.

Light waves, as they propagate through a medium, experience a temporal delay. This delay can unveil crucial information about the underlying structural and compositional characteristics. Quantitative phase imaging (QPI) is a cutting-edge optical technique that reveals variations in optical path length as light moves through biological samples, materials, and other transparent structures. Unlike traditional imaging methods that rely on staining or labeling, QPI allows researchers to visualize and quantify phase variations by generating high-contrast images that enable noninvasive investigations crucial to fields such as biology, materials science, and engineering.

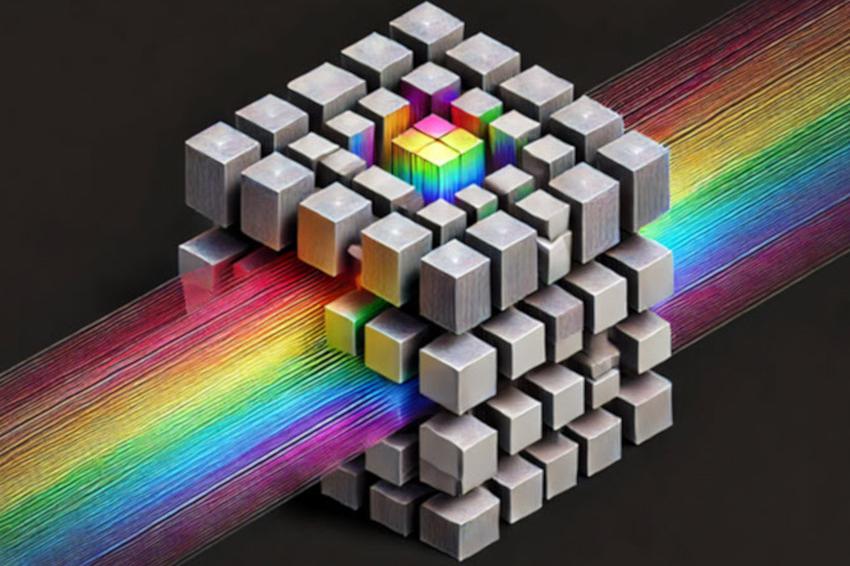

Now, researchers at the University of California, Los Angeles UCLA, introduce a cutting-edge approach to 3D QPI using a wavelength-multiplexed diffractive optical processor. The new approach offers an effective solution to a bottleneck posed by traditional 3D QPI methods, which can be time-consuming and computationally intensive. The team developed a wavelength-multiplexed diffractive optical processor capable of all-optically transforming phase distributions of multiple 2D objects at various axial positions into intensity patterns, each encoded at a unique wavelength channel.

The design allows for the capture of quantitative phase images of input objects located at different axial planes using an intensity-only image sensor, eliminating the need for digital phase recovery algorithms. “We are excited about the potential of this new approach for biomedical imaging and sensing,” said Aydogan Ozcan. “Our wavelength-multiplexed diffractive optical processor offers a novel solution for high-resolution, label-free imaging of transparent specimens, which could greatly benefit biomedical microscopy, sensing, and diagnostics applications.”

The innovative multiplane QPI design incorporates wavelength multiplexing and passive diffractive optical elements that are collectively optimized using deep learning. By performing phase-to-intensity transformations that are spectrally multiplexed, this design enables rapid quantitative phase imaging of specimens across multiple axial planes. This system's compactness and all-optical phase recovery capability make it a competitive analog alternative to traditional digital QPI methods.

A proof-of-concept experiment validated the approach, showcasing successful imaging of distinct phase objects at different axial positions in the terahertz spectrum. The scalable nature of the design also allows adaptation to different parts of the electromagnetic spectrum, including the visible and IR bands, using appropriate nano-fabrication methods, paving the way for new phase imaging solutions integrated with focal plane arrays or image sensor arrays for efficient on-chip imaging and sensing devices.

This research has significant implications for various fields, including biomedical imaging, sensing, materials science, and environmental analysis. By providing a faster, more efficient method for 3D QPI, this technology can enhance the diagnosis and study of diseases, the characterization of materials, and the monitoring of environmental samples, among other applications. (Source: SPIE)

Link: Bio- and Nano-Photonics Laboratory, University of California, Los Angeles UCLA, Los Angeles, USA