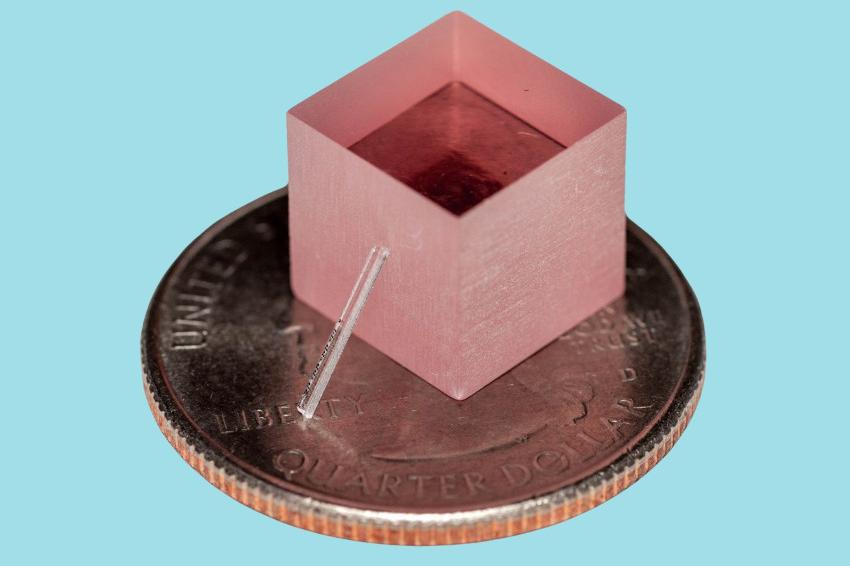

A chip-scale titanium-sapphire laser

16.08.2024 - New approach for cheaper and massively scalable laser-array systems for several applications.

As lasers go, those made of titanium-sapphire (Ti:sapphire) are considered to have unmatched performance. They are indispensable in many fields, including cutting-edge quantum optics, spectroscopy, and neuroscience. But that performance comes at a steep price. Ti:sapphire lasers are big, on the order of cubic feet in volume. They are expensive, costing hundreds of thousands of dollars each. And they require other high-powered lasers, themselves costing $30,000 each, to supply them with enough energy to function. As a result, Ti:sapphire lasers have never achieved the broad, real-world adoption they deserve – until now. In a dramatic leap forward in scale, efficiency, and cost, researchers at Stanford University have built a Ti:sapphire laser on a chip. The prototype is four orders of magnitude smaller and three orders less expensive than any Ti:sapphire laser ever produced.

“This is a complete departure from the old model,” said Jelena Vučković. “Instead of one large and expensive laser, any lab might soon have hundreds of these valuable lasers on a single chip. And you can fuel it all with a green laser pointer.” “When you leap from tabletop size and make something producible on a chip at such a low cost, it puts these powerful lasers in reach for a lot of different important applications,” said Joshua Yang, a doctoral candidate in Vučković’s lab.

In technical terms, Ti:sapphire lasers are so valuable because they have the largest gain bandwidth of any laser crystal, explained Yang. In simple terms, gain bandwidth translates to the broader range of colors the laser can produce compared to other lasers. It’s also ultrafast, Yang said. Pulses of light issue forth every quadrillionth of a second. But Ti:sapphire lasers are also hard to come by. Even Vučković’s lab only has a few of these prized lasers to share. The new Ti:sapphire laser fits on a chip that is measured in square millimeters. If the researchers can mass-produce them on wafers, potentially thousands, perhaps tens-of-thousands of Ti:sapphire lasers could be squeezed on a disc that fits in the palm of a human hand.

“A chip is light. It is portable. It is inexpensive and it is efficient. There are no moving parts. And it can be mass-produced,” Yang said. “What’s not to like? This democratizes Ti:sapphire lasers.” To fashion the new laser, the researchers began with a bulk layer of Titanium-sapphire on a platform of silicon dioxide (SiO2), all riding atop true sapphire crystal. They then grind, etch, and polish the Ti:sapphire to an extremely thin layer, just a few hundred nanometers thick. Into that thin layer, they then pattern a swirling vortex of tiny ridges. These ridges are like fiber-optic cables, guiding the light around and around, building in intensity.

“Mathematically speaking, intensity is power divided by area. So, if you maintain the same power as the large-scale laser, but reduce the area in which it is concentrated, the intensity goes through the roof,” Yang says. “The small scale of our laser actually helps us make it more efficient.” The remaining piece of the puzzle is a microscale heater that warms the light traveling through the waveguides, allowing the Vučković team to change the wavelength of the emitted light to tune the color of the light anywhere between 700 and 1,000 nanometers – in the red to infrared.

Vučković, Yang, and colleagues are most excited about the range of fields that such a laser might impact. In quantum physics, the new laser provides an inexpensive and practical solution that could dramatically scale down state-of-the-art quantum computers. In neuroscience, the researchers can foresee immediate application in optogenetics, a field that allows scientists to control neurons with light guided inside the brain by relatively bulky optical fiber. Small-scale lasers, they say, might be integrated into more compact probes opening up new experimental avenues. In ophthalmology, it might find new use with Nobel Prize-winning chirped pulse amplification in laser surgery or offer less expensive, more compact optical coherence tomography technologies used to assess retinal health.

Next up, the team is working on perfecting their chip-scale Ti:sapphire laser and on ways to mass-produce them, thousands at a time, on wafers. Yang will earn his doctorate this summer based on this research and is working to bring the technology to market. “We could put thousands of lasers on a single 4-inch wafer,” Yang says. “That’s when the cost per laser starts to become almost zero. That’s pretty exciting.” (Source: Stanford U.)

Link: Nanoscale and Quantum Photonics Lab, Stanford University, Stanford, USA