Flexible laser plastic welding as an addition to AM

Highly efficient welding of additively manufactured thermoplastic components

Individualization, shorter product cycles and prototyping are leading to increased use of additive manufacturing (AM) in industry. A reliable and versatile process like laser plastic welding is needed to join parts with other additively manufactured or injection molded parts. AM is even more economical than injection molding (IM) for small quantities due to the short time from model to functional part, and additional tooling being unnecessary.

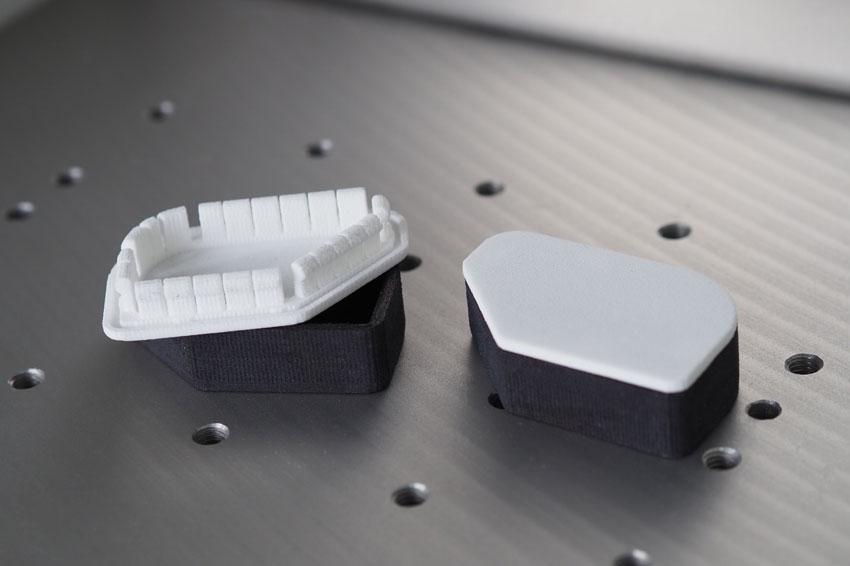

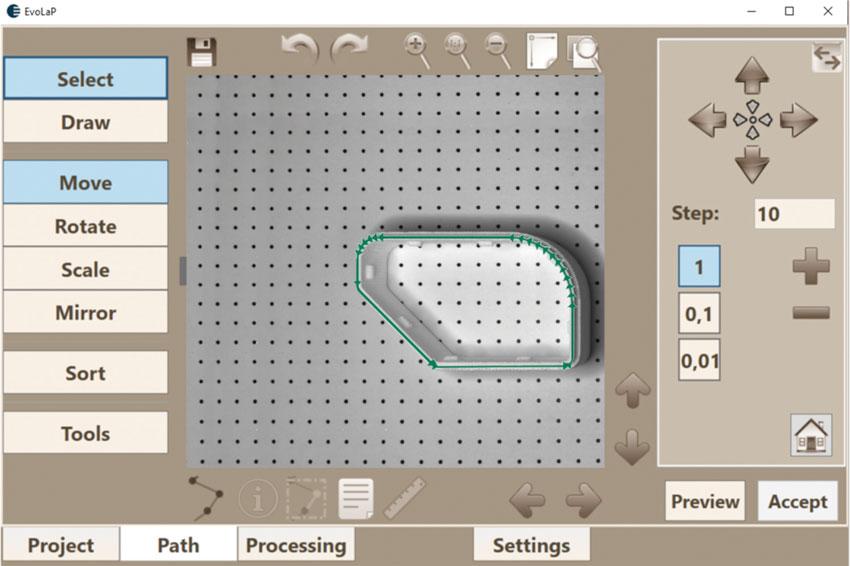

However, 3D printed parts have challenging optical properties, such as decreased transmission and high scattering of the laser within the part. A method was developed to pretreat the AM parts with a second laser to address this challenge. Additionally a design which enables the integration of clips into the additively manufactured parts in order to provide an easier clamping method was developed. For testing purposes, PA12 demonstrator parts were manufactured both additively and by injection molding, enabling different material combinations to be welded and investigated that are interesting for different application cases.

Evosys Laser has presented their capabilities at Stuttgart Laser Technology Forum this week and discuss the procedure in a new technical article which is available online and will be printed in the September issue of PhotonicsViews. The experts will also be available during MedtecLIVE, Booth 1-931.

Reference: Lea Kroth & René Geiger (Evosys Laser): Flexible laser plastic welding as an addition to AM: Highly efficient welding of additively manufactured thermoplastic components, PhotonicsViews, first published online: 06 June 2024; DOI: https://doi.org/10.1002/phvs.202400015