New record in laser cooling

26.04.2024 - German and American researchers succeed in cooling silica glass by 67 Kelvins.

Cutting, drilling, welding – we usually associate laser light with the heating of materials. But under specific circumstances, it is also possible to cool materials through radiation with laser light. However, laser radiation can also cause cooling in solids. This paradoxical effect becomes possible through anti-Stokes fluorescence cooling. In this process, a special, high-purity material is excited via laser light radiation. Due to the difference in energy between the excitation laser and the radiation emitted by the material, i.e., the fluorescence, energy is extracted from the material in the form of heat. Now, a research team from the Fraunhofer Institute for Applied Optics and Precision Engineering IOF and the University of New Mexico have succeeded in cooling silica glass by 67 kelvins through optical laser cooling.

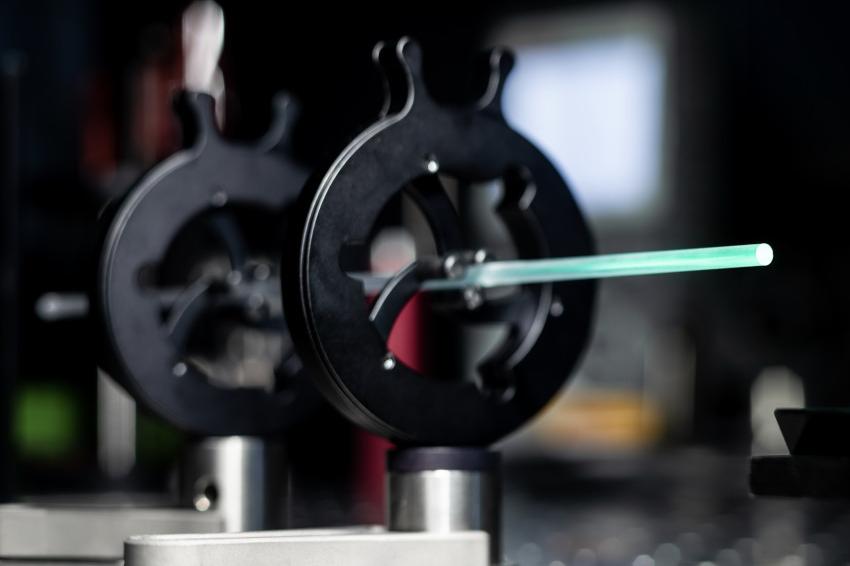

For many years, the cooling of silica glass was considered impossible. But in 2019, researchers from Jena and Albuquerque were able to prove the laser cooling of ytterbium-doped silicia glass for the first time. Back then, the cooling only reached 0.7 kelvins from room temperature. To overcome the previous cooling threshold, the specific process for manufacturing the doped material as well as its exact composition were optimized. Moreover, the excitation lasers used for the measurements were improved. As a result, the researchers have now achieved a new record-breaking cooling: Through the radiation of an ytterbium-doped silica rod by an excitation laser with a power of 97 watts and a wavelength of 1032 nanometers, the researchers were able to prove a temperature reduction from room temperature by 67 kelvins within two minutes.

Because of this new development, novel, extremely stable lasers and low-noise amplifiers for precision metrology or quantum experiments can be developed in future. Moreover, the optimized process can advance vibration-free cooling and thereby open up new potentials for application in materials analysis and medical diagnostics through cryomicroscopy and gamma spectroscopy.

The potential use of the material in fibers is particularly interesting. In future, the new process could be used to develop high-performance fiber lasers that do not have to deal with the limiting effects of thermal instability. The new process represents a significant advance in laser cooling and, according to the experts’ theoretical considerations, does not mark the greatest possible temperature reduction using laser light yet. (Source: Fh.-IOF)

Links: Center for High Technology Materials, University of New Mexico, Albuquerque, USA • Laser & Fiber Technology, Fraunhofer Institute for Applied Optics and Precision Engineering, Jena, Germany