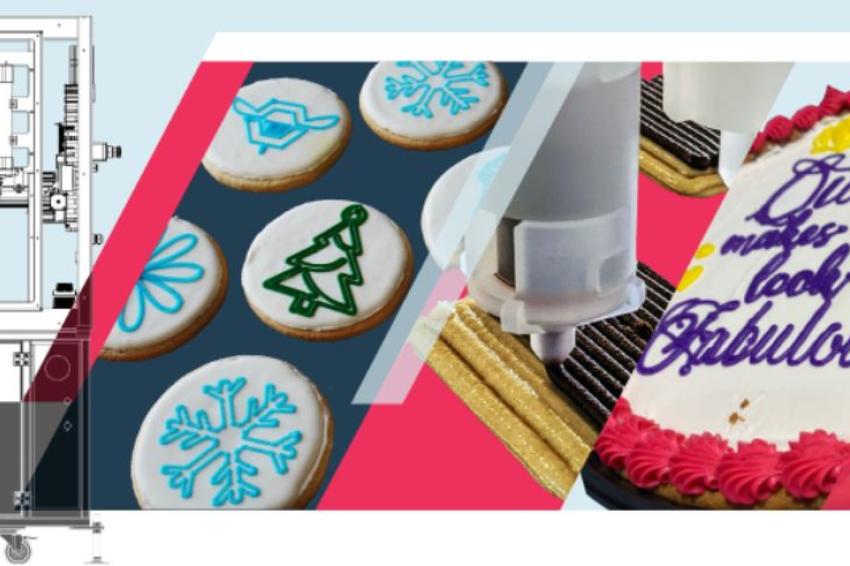

3D Sensor for Real-Time Cake Decoration

A new cake app in US supermarkets solves the challenge of decorating a customized cake on the spot with the aid of the world’s fastest 3D laser line profiling

Anyone who has ever decorated a cake knows how much time the decoration takes if you want to achieve a nearly perfect result in the end and impress with your delicacy. Especially in the US, the so-called frosting of cakes is a big issue, because Americans love brightly colored decorations and food coloring which has always been a must in terms of cake design. It is precisely this fascination with decorations that the US startup Beehex Automation is dedicated to, and it wants to cause a sensation in America with its solution for designing cakes.

Making an idea reality

The idea: to develop a system for the automatic labeling of cakes that can be used in any supermarket. The challenge: an uncomplicated application that responds flexibly to the size, texture, and background while working reliably. The solution: food design using 3D sensors from AT – Automation Technology. The special ingredient: a novel 3D sensor technology which currently offers the world’s fastest 3D laser line profiling thanks to the new C6 sensor.

For this C6 sensor the manufacturer developed a sensor chip with the novel feature “Widely Advanced Rapid Profiling” (WARP). The new imager offers a resolution of 3072 pixels per row and enables the C6 profiler to generate high resolution 3D scans. Furthermore, it is so fast that a profile speed of 38kHz or more can be reached depending on the height range of the application. This suddenly gives applications such as those in the food industry a completely new dimension.

Currently the World’s Fastest 3D Sensor on the Market

“Our intention was to launch a 3D sensor that would be revolutionary in terms of innovation and that is exactly what we have achieved with the new C6 series. The new 3D sensors are unique in their combination of resolution and speed, so with their features we are opening up completely new horizons in 3D image processing,” says André Kasper, founder and CTO of AT. And further: “Equally worth mentioning are also the Multipart and Multipeak features. Multipart enables the simultaneous output of up to ten different image features, and thanks to Multipeak, even highly reflective materials can be scanned without disturbing reflections.”

And it was precisely this expertise that ultimately helped the startup company Beehex Automation, which had been looking for a partner from whose many years of expertise it would benefit in the field of 3D image processing: “We decided to work with AT because we have enormously demanding requirements due to the different nature of the cakes to be labeled, which not every component manufacturer can fulfill. However, with its C6 sensor, AT has a 3D solution in its portfolio that is, on the one hand, compatible with our software for evaluating the data and, on the other, can be used flexibly,” explains Benjamin Feltner, Managing Director of Beehex Automation.

The contact with AT had been established through its American sales partner Movitherm, with whom AT has already been working for more than 15 years. “Especially in the field of 3D sensors, there is no other supplier worldwide that offers such modular solutions as AT. The company is one of the innovation drivers in the machine vision industry and has established itself with many global customers as a reliable manufacturer of high-quality components with its products. With such a partner at its side, a startup company like Beehex Automation will be able to quickly make a name for itself,” mentions David Bursell, Vice President of Business Development of Movitherm.

Convincing retailers

Since it is less common in the US than in Germany to buy one’s cakes in a traditional bakery, Beehex would like to convince retailers in particular of its idea and establish itself in the food industry as the first point of contact for the individualization of cakes. “Cakes have been totally popular in this country for decades and always will be. People will still be interested in great cakes for the next hundred years. That’s why this is a particularly exciting market for us to work in, where there are always challenging things to discover,” Feltner continued.

He is particularly proud of the development of his team. Eleven people are now working on the constant further development of the cake application, which requires a great deal of patience and also a lot of technical know-how. The CEO further tells that they were even able to win engineers from large companies like Tesla for their idea, as they prefer to contribute their knowledge and want to see the company continue to grow. Above all, he says, the steep learning curve is the motivation that keeps everyone at our company constantly pushing forward.

Contact

AT - Automation Technology GmbH

Hermann-Bössow-Str. 6-8

23843 Bad Oldesloe

Germany

+49 4531 88011 0

+49 4531 88011 20