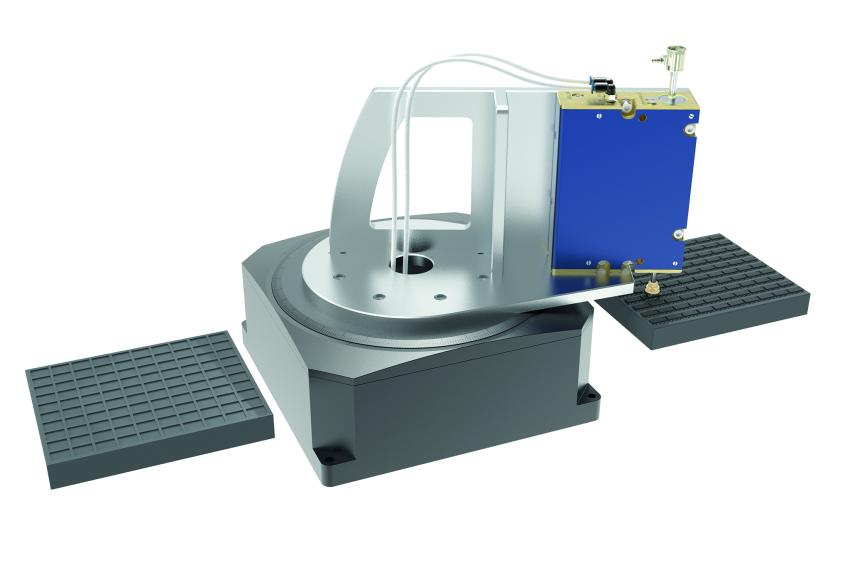

Rotary lift actuator for quick pick-and-place tasks

Steinmeyer Mechatronik

It allows both a sensitive and very fast combined rotary and linear movement and guarantees process-reliable 24/7 production thanks to the integrated controller, user-friendly plug-and-play technology and smart self-diagnosis.

The industrial-grade rotary-lift actuator enables the component to be positioned to be removed from the automatic magazine feed, recorded in position and, if necessary, corrected and positioned with controlled pressure force. The internal control with field bus interface is plug-and-play capable and is located directly in the positioning unit. This makes the system compact, powerful and service-friendly. Another advantage of the embedded control electronics: By monitoring certain parameters - such as maximum speed during initialization (self-diagnostics) or following errors during operation - errors or wear can be detected early and machine downtimes can be avoided by intervening in good time. The connection via EtherCAT or CAN enables worldwide remote maintenance, diagnostics, updates, programming or parameterization. It allows both a sensitive and very fast combined rotary and linear movement and, thanks to the integrated control, user-friendly plug-and-play technology and smart self-diagnosis a process-reliable 24/7 production.

The industrial-grade rotary-lift actuator enables the component to be positioned to be removed from the automatic magazine feed, recorded in position and, if necessary, corrected and positioned with controlled pressure force. The internal control with field bus interface is plug-and-play capable and is located directly in the positioning unit. This makes the system compact, powerful and service-friendly. Another advantage of the embedded control electronics: By monitoring certain parameters - such as maximum speed during initialization (self-diagnostics) or following errors during operation - errors or wear can be detected early and machine downtimes can be avoided by intervening in good time. The connection via EtherCAT or CAN enables worldwide remote maintenance, diagnostics, updates, programming or parameterization.

Contact

Steinmeyer Mechatronik GmbH

Fritz-Schreiter-Str. 32

01259 Dresden

+49 351 88585 0