Inspection Systems for Glass Fiber Production Processes

Web Inspection and Monitoring Platform Determines the Cause of Glass Fiber Production Defects

The strength and versatility of glass as a fiber makes it unique as an industrial textile material. Nonwoven end products based on glass fibers have a huge market and can be found almost everywhere – in ceiling tiles, cushion vinyl flooring, insulation, wallpapers, and surfaces, geotextiles, batteries, and of course roofing materials, as well as in many other applications.

Vast Variety of Features and Applications

Glass fiber, as a basic component, is an excellent composite material and offers numerous advantages that give their esulting products unique properties. These nonwovens are known for excellent thermal insulation, high tensile strength, and extreme moisture repellency.

Glass fibers exhibit useful bulk properties such as hardness, transparency, resistance to chemical attack, stability, and inertness, as well as desirable fiber properties such as strength, flexibility, and stiffness. They are used in the manufacture of structural composites, printed circuit boards, and a wide range of special-purpose products. Some of the most common applications for glass fiber nonwovens include infrastructure, buildings and construction, pipes and tanks, transportation, consumer goods, oil and gas, chemical, industrial and corrosion.

Determining Defects

Many filter media are fibrous in nature, and their properties depend on media thickness, fiber diameter, fiber orientation, and pore size distributions. One major purpose in the inspection of glass fibers is to find defects and/or formation weaknesses that will cause degradation of strength or filtration of the material shipped to the end customer. A further reason is to understand the web forming process better, particularly when and why defects appear. This root cause analysis is moving more and more to become the focus.

Glass Fiber Mats Based on Wetlaid

Glass fiber mats can be used for a very wide range of applications, and this is a growing market. Different types of lines are available – from small to large capacities. To ensure good web formation and a lower consumption of expensive chemicals, it is important to give the fibers enough room to move freely by applying sufficient turbulence to the water-fiber suspension, and to lay the fibers with the best fiber orientation, making sure that they are well distributed.

The volume of wetlaid nonwovens materials for construction interiors is continuing to develop. Yet, it is not only the volume of these materials that is growing but also the demand for high-quality materials.

More and more buildings and houses are being built and rebuilt worldwide. This results in an increasing demand for construction materials. Manufacturers are developing products that are easier and quicker to apply and require less post-treatment than plasterwork or paintwork.

Finding the Perfect Fiber Distribution

An important part of these developments is based on wetlaid nonwovens glass fiber material. For example, the paper and cardboard materials used as facers and backing material on gypsum board dry-wall and polyiso roofing panels are now being replaced by coated glass fiber veils. Increasingly, glass fiber veil is used in applications where aesthetics is very important, such as ceiling tiles and wallpaper. The more traditional applications, where aesthetics are less demanding for glass fiber veil – such as reinforcement material for vinyl flooring, carpets and bituminous roofing – require flatter materials with higher tensile strength.

Glass fiber veil is also used as a filtration material, and for battery separators. Good distribution of the glass fibers is essential in these applications. These developments require glass fiber producers to improve the properties of their products.

A homogeneous mat with perfect fiber distribution is needed more than ever to meet the end-user requirements. The market expects products with perfect fiber formation – this is where Ametek Surface Vision’s Smartview inspection system comes in, as it will document the web quality.

Inspection Systems for Glass Fiber Production Processes

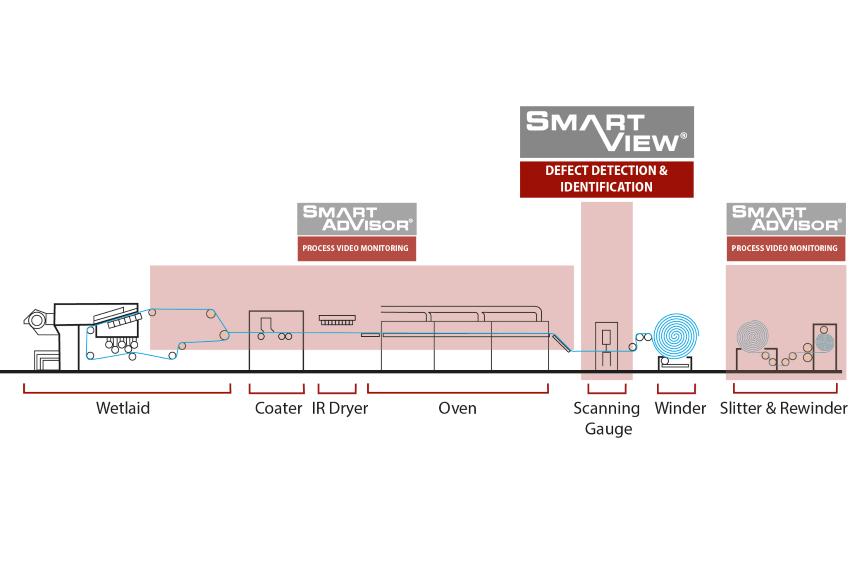

To inspect glass fiber processes, Ametek Surface Vision uses its Smartview web inspection and Smartadvisor web monitoring products together in a unified platform called Smartsync. This total vision integration combines the power of advanced Smartview classification with the flexible, multi-position camera technology of Smartadvisor. As a result, the operator can rapidly determine the root cause of any defects and take the necessary corrective action. An integrated fault map provides an accurate process quality overview, while classified defects are synchronized with the associated video files from upstream cameras. An integrated database provides comprehensive reporting for all visual anomalies

Integrated database for reporting of all visual anomalies

The Smartview system uses multiple cameras and lights arranged on glass fiber production processes. This can range from an optimized optical arrangement to selecting the suitable light to highlight topographical (3D) defects like wrinkles or contamination, missing binder, or any other damage of the web.

To round up the application requirement, patented air knives are used to reduce the maintenance work, while special cooling components embedded in the mechanical design allow the system to be installed close to the dryer section.

Web Monitoring for Capturing and Storing Sheet Breaks

Smartadvisor’s web monitoring technology provides the capability to capture and store sheet breaks and corresponding sheet defects, from root cause to failure. Images from multiple camera locations are automatically synchronized to a continuous flat sheet process, such as those in the paper, plastics, nonwovens, and metals industries. This multi-camera synchronized view ensures that the cameras automatically synchronize to web speed and location, so that current and historical images are presented seamlessly. Smartadvisor allows direct scan-back from live video, with up to 72 hours of recorded history, for easy and clear identification of upset root causes.

Conclusion

The growing use of glass fiber in a wide variety of nonwoven applications across many industries has increased the need for accurate, automated inspection. This high-quality inspection can be provided by a combination of Ametek Surface Vision’s Smartview and Smartadvisor products, which together provide defect detection and identify the root cause of those defects.

An automated system supports high-speed production, so there is no loss in productivity while inspection takes place, while the level of detail inspected is far greater than that of the naked eye. By using an automated inspection system, manufacturers of glass fiber nonwoven materials can assure their product quality, maximize yields, and significantly reduce customer complaints.

Author

Volker Kölmel, Global Manager Plastic, Nonwovens & Paper

Contact

Ametek Germany GmbH

Rudolf-Diesel-Str. 16

64331 Weiterstadt

Germany

+49 6150 543 70 64

+49 6150 543 15 00