Pump monitoring in the drive

Baumüller

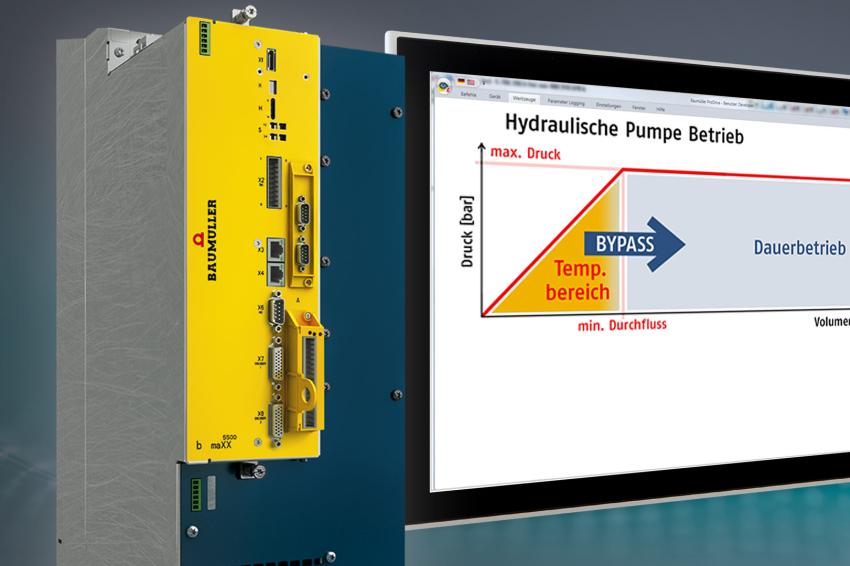

In servo-hydraulic applications, a thermal overload can occur in the machine cycle with long holding times of high pressures and low flow rates. This increases wear and can lead to premature pump failure. The current thermal pump utilization is determined and monitored using a dynamic calculation model. The utilization is calculated using the speed, pressure and, if available, the oil tank temperature directly in the servo converter. The calculation takes place with a very short cycle time of 1ms.

If the specified threshold value for utilization is reached, hydraulic bypasses are switched on to relieve the pump, which ensure a higher flow rate and better heat dissipation. This shifts the operating point of the pump from the temporarily permissible operating range to the permanently permissible operating range and prevents damage caused by overheating.

Contact

Baumüller Nürnberg GmbH

Ostendstr. 80-90

90482 Nürnberg

Germany

+49 911 54 32 0

+49 911 54 32 130